Procurement management: optimizing business processes. How to optimize the purchasing system in a retail store How to optimize purchasing at an enterprise

Any enterprise needs goods, works or services used for production. The process of acquiring them on the market, from third-party suppliers is called procurement, and the activity for their implementation is called procurement. Its correct organization requires:

· accurate knowledge of the components of production costs and justification of the need for purchased goods, works, services;

· establishing priorities both in terms of purchased products (quality, quantity, contract terms, etc.) and between suppliers (legal capacity, qualifications);

· the presence of an organizational decision-making scheme when planning and implementing procurement, rules for their implementation;

· interaction with financial and tax planning.

The main stages of procurement activities are presented in Fig. 11.3.1.

Rice. 11.3.1. Purchasing cycle

A significant part of the consumed products can not only be purchased externally, but also produced by its own functional departments. Therefore, the first and most important issue in organizing procurement activities is its planning, including determining the need for goods, works, services, dividing them into those that will be produced within the enterprise and those that should be purchased from third-party suppliers (the term is often used for works and services “outsourcing” - attracting external resources to perform non-core activities for the enterprise). The scope of outsourcing is extremely wide - from hiring consultants, a construction or repair organization to transferring such purely “internal” matters as maintaining accounting records to a third-party company.

After making a purchasing decision, a market analysis of the purchased products should be conducted. Such an analysis is necessary to determine the price level. At this stage, the requirements for the product, the supplier and the terms of the future contract are clarified, and the situation with the possible number of potential suppliers is predicted.

The next stage is the direct organization of the purchase: its preparation, execution and signing of the contract. Preparation includes the formalization of all customer requirements in documents intended for third-party suppliers. Conducting a procurement involves receiving proposals, evaluating them and selecting the best one. The conclusion of the contract is carried out in accordance with the procedure established by the enterprise. The contract is fulfilled and thus the customer’s need for products is satisfied. Then a new need arises and the purchasing cycle repeats.

The above looks simple and quite obvious for any company. However, why is procurement management a problem that requires significant effort to solve? The fact is that a specific enterprise, making a specific purchase, risks ending up in the zone market failure- a situation in which the free action of market forces does not lead to an optimal outcome of the transaction for at least one party. In other words, even if there is an established market for a particular product and there is a market price, this does not mean that a specific customer will receive the product at this (or close) price when purchasing. There are several reasons for this phenomenon, but the main ones are:

· unqualified actions of purchasing managers and, as a result, errors in choosing a supplier. This is often facilitated by objectively existing asymmetry of information - the supplier usually knows everything about his products, but the customer may simply not have information about the real, market relationship between the quality of the purchased product and its price;

· unfair actions of purchasing managers (primarily inflating prices in order to obtain various types of incentives from suppliers).

Measures that reduce the likelihood of incorrect actions by employees responsible for procurement can be generally divided into two groups: work with personnel and procedural regulation. Work with personnel is standard and involves targeted selection of people taking into account their professional knowledge and certain psychological properties, a system of rewards and punishments, and training. Procedural measures imply such regulation of the actions of purchasing managers so that the decisions they make, regardless of personal preferences and personal motivation, are carried out in the interests of the enterprise. In this case, regulation can go in two directions. The first means that the status of those responsible for procurement increases, and decision-making becomes more complicated (for example, the number of visas on documents increases). In individual cases, this works quite successfully, but in general, management regulation leads to overload of top managers. The second direction is based on the application of mandatory procedures that must be followed by purchasing employees for each purchase with a value above a certain value. These procedures assume:

· actions aimed at achieving a reasonable level of competition among potential suppliers where possible and where impossible - increased internal control;

· honest and reasonable selection of the most preferable offers with a comprehensive analysis of benefits and costs (primarily price and quality of products).

Thus, the main goal of market-based procedural measures is to achieve a reasonably high level of competition among proposals that are subject to transparent, controlled evaluation. Only where there is no such competition is it possible to apply management regulation. That is why this system is often called “competitive”, and procurement organized in this way is often called “competitive procurement”. Any purchasing employee, being placed within the strict framework of competitive procedures, is forced to act effectively (from the point of view of the interests of the organization), since properly organized competition reveals true, market prices for purchased products, and transparent, controlled procedures for selecting the best offer make wrong decisions noticeable .

When organizing procurement activities at enterprises, the experience of government procurement*, the regulation of which has a long history and extensive world practice, is useful. However, it should be understood that blindly copying the experience of public procurement, without taking into account the goals and objectives of the commercial customer, may lead not to an increase, but to a decrease in the efficiency of the procurement activities of a given company.

One of the most common procurement procedures competitive procurement is bidding - a method of concluding contracts in which, according to pre-announced rules, several competing proposals are attracted by a certain date in order to ensure the most favorable terms of the transaction for the customer. The main, key principle of bidding is competition. According to the legislation of the Russian Federation (Civil Code of the Russian Federation, Articles 447-449), trading takes place in the form of a competition or auction. The most common when purchasing contest.

“The winner of the auction is the person who offered the highest price, and in the competition - the person who, according to the conclusion of the competition commission, pre-appointed by the auction organizer, offered the best conditions” [Civil Code of the Russian Federation, Art. 447, paragraph 4].

Auction- a special case of competition. In practice, an auction is understood as any procedure in which the only evaluation criterion is the price - the maximum (for sales) or minimum (for purchases). In the latter case, the concepts of “reverse auction” or “price competition” are also used. A broader interpretation of the concept of “auction” is proposed, for example, in some EU directives regulating procurement issues. From the meaning of the electronic auction procedure described there, it follows that the winner is determined by parameters that allow quantitative measurement and unambiguous ranking according to these parameters (price, delivery time, mechanism power, etc.).

Since the decision on the winner of the competition is made by the competition commission, no company manager, even the highest rank, can disagree with the decision of the competition commission. The contract with the winning bidder is mandatory. Any person can take part in an open competition (auction), while in a closed competition only those specially invited (the circle of participants is limited by the organizer of the competition). The minimum period for any competition or auction is 30 days.

The competition involves a number of stages specified by law:

preparation of notice and tender documentation by the customer, appointment of a tender commission that will select the winner;

publication of a notice in an open competition and direct mailing in a closed competition (from this moment the competition is considered announced), etc.;

The evaluation of competitive proposals, as a rule, takes place in two stages - screening out unacceptable proposals (selection stage) and selecting the best decision from the remaining ones by the competition commission (evaluation stage); in a price competition (reverse auction), the competition commission rejects unacceptable proposals and selects proposals with the lowest price from the remaining ones. That is why in the electric power industry the bidding procedure with selection at the minimum price is called “price competition”.

Non-competitive procedures differ from auctions in the absence of an obligation for the customer to enter into an agreement with the winner, the possibility of changing or canceling the decision on the winner, short deadlines, simplified regulations and the fact that they are not regulated in detail by the domestic Civil Code. Most bidding is competitive and procedurally similar to a competition (request for proposals, request for prices, competitive negotiations). There is also a non-competitive, non-alternative procedure - (“purchase from a single source”), when the supplier is determined in advance, without comparing competing offers, for example, during additional purchases, purchases in conditions of lack of time, etc.

The algorithm for conducting a request for proposals is defined by law.

If the customer is not satisfied with the proposals or, after analyzing them, sees that the initial requirements should be changed, he, after evaluating the initial proposals, can prepare a new version of the request for proposals documentation and repeat the entire cycle until either a winner is selected or the procurement is terminated .

Request for prices is much simpler both in terms of procedures and documentation. It is carried out as follows:

· preparation of notification and documentation of the request for prices (only a notification can be prepared and issued);

· publication of a notification when a request is open and direct mailing when a request is closed;

· receipt by participants of the request for quotations documentation (if any) and their preparation of their price proposals;

· receiving offers;

· evaluation of proposals, rejection of unacceptable ones and selection of the cheapest from the remaining ones;

· conclusion of an agreement with the winner.

When conducting a request for prices (and it is used for simple, unambiguously described products), all the main conditions are clearly recorded: products, requirements for their quantity and quality, essential terms of the contract.

Competitive negotiations- detailed minutes of negotiations with a certain number of participants, usually at least three.

There is no concept in Russian civil law "tender". It came to us from international practice and has become synonymous with the words “bidding” or “competition”, since the procedures are very similar. But in international practice, the customer has the right to refuse to hold a tender at any time or to reject any application or even all applications without giving reasons. In addition, the results of the tender may be approved by someone (in addition to the tender commission). In essence, the tender, unlike Russian auctions, does not impose on its organizer the obligation to select the winner and conclude an agreement with him. Even experts often forget to take this fundamental difference into account, which leads to legal conflicts when foreign documents are used uncritically in Russia.

The availability of certain methods and the conditions for their use depend on the goals and objectives of the customer. For example, in the public procurement system (both in Russia and in the world), the main priorities are the fight against possible corruption and saving budget funds for a specific purchase. Consequently, the set of rules and procedures here is focused precisely on these goals as the main ones and therefore is often simple (open and closed competition, request for prices, exclusion of any negotiations, uncontested procurement is extremely difficult). A special feature of competitions in the electric power industry is the possibility of rebidding, i.e. the best participants who have passed the qualifying stage are given the opportunity to increase the preference of their proposals by reducing the price, while other conditions remain unchanged. This allows for increased price effects from procurement, but makes choosing a winner a more complex process; Rebidding is not provided for in the public procurement system.

Practice shows that purchasing organizations follow three simple rules:

· the degree of regulation depends on how public the economic entity is: the more public it is, the more stringent the procurement regulation system it builds, therefore these are the rules for purchasing products for public authorities, within the framework of projects of international financial organizations;

· regulated procurement is carried out using a wide range of procedures, including competitions and non-competitive methods;

· any procurement regulation system must be just that: a system, which implies the presence of the following elements:

a) the regulatory environment (a set of regulatory documents describing procurement methods and the conditions for their selection, the powers and responsibilities of purchasing employees); b) the established organizational structure for procurement management and control;

c) trained personnel for procurement; d) well-established procurement infrastructure (information support, e-commerce tools, certification, professional consultants).

Another important element of the system is the political will of the leadership, the disposition to unconditionally implement the rules of regulation.

It would be a mistake to assume that the main goal of the competition (and competitive procurement in general) is price savings. The main goal of proper organization of purchasing activities at an enterprise is to achieve market prices for purchased products through competitive procedures. When purchases are planned based on real prices, but with some “reserve”, the correct conduct of a competition in stable markets leads to the identification of this “reserve” in the form of savings, usually 3-7%. However, once competitive procedures are introduced, cost savings can be very significant. There have been cases when, during the initial holding of open tenders where this had not happened before, prices fell several times. In addition, competitions can quickly identify changes in market prices by identifying those participants in the market who, through the use of new operating techniques, achieve competitive advantages and reduce prices.

One way to improve a company's efficiency is to optimize its supply. And since there is no universal recipe for solving this problem, it is best to build some kind of diagnostic map and indicate on it the key areas that should be constantly in the focus of attention of the purchasing director. You can use various methods and tools. Sergey Kuzovkin, partner at BearingPoint, talks about them.

Working in key areas of procurement can have a significant impact on a company's financial performance. Direct impact is achieved by:

- reducing the total cost of purchased materials, services and costs for implementing the supply function;

- release of working capital from current activities.

Indirect influence occurs through several mechanisms:

- increasing the level of service in servicing customers within the company and the quality of purchased materials;

- reducing dependence on the human factor;

- increasing procurement transparency.

Let's look at areas that have a direct impact on the company's financial performance and provide a set of possible measures for each of them.

Reducing the total cost of purchased materials and services

Saving on goods and services that a company needs in the production process, without compromising the quality of the final product, is a difficult task, but it can be done. Here you can work in the following areas.

Consolidation of procurement volumes. Suppliers often offer more favorable terms when purchasing goods or services in large quantities. To increase the scale of purchases and receive discounts in order to reduce the cost of one unit of purchased products, you can organize centralized supply of several enterprises purchasing the same type of products. Another tool proven by many companies is concluding long-term contracts with suppliers. In this case, counterparties agree to soften the terms of the contract, since they have a contract to purchase certain volumes of products from them.

Stimulating competition. In a competitive environment, suppliers will go to great lengths to win a contract. Information transparency of trading is of great importance here. If the customer is honest with his suppliers and both parties understand the rules of the game well, their risks will be minimal, which means that the desire to participate in procurement will increase. It is also necessary to constantly expand the supplier base, look for partners in other regions and stimulate the development of already proven partners. After all, only the purchasers themselves can indicate what requirements the product/service must meet and how to comply with them.

Reducing the share of urgent purchases. Urgency is usually a major constraint. You have to buy from suppliers who do not offer the best conditions, make less than optimal transportation decisions, etc. Therefore, more attention needs to be paid to planning resource requirements and optimizing this process. Possible activities in this area are given in Table. 1.

Reducing the cost per unit of purchased materials and equipment and services (Table 1)

|

Economies of scale |

Consolidation of quarterly and annual needs (long-term contracts); Consolidation of lots; Centralization of supply to several enterprises/regions for selected categories |

|

Stimulating competition |

Information transparency for suppliers of procurement rules; Expanding the supplier base: market requests, pre-qualification, compiling a long list of subcategory suppliers; Supplier quality management, - motivational schemes depending on quality; Participation in preparation of production from potential suppliers; Electronic procurement, auctions; Refusal of quotas, transfer of position volumes to one supplier (with possible options to the second at the price) |

|

Reducing costs by reducing the share of urgent purchases |

Optimization of planning of resource requirements and procurement; Reducing procurement time “best practices”; Normalization of reference information (RNI), collapse of duplicates |

|

Reducing the total cost of supply by calculating export parity and possible changes in the supply basis |

Netback calculation at manufacturing plants, price calculation; Changing the delivery basis and/or introducing prices using formulas (depending on the dynamics of the underlying asset) |

|

Reduced TCO |

Analysis of the impact of the quality of purchased materials on productivity or consumption; Calculation of TCO for the planned output volume (cost of acquisition, maintenance and repair, downtime and rejection, mean time between failures, other significant TCO components); TCO Scenario Analysis |

|

Reducing the overall cost of work due to detailing and possible specialization of contractors |

Separation of the cost of materials and work in proposals, breakdown of costs by type of work; Component-by-component comparison of the cost of applicants; Determining the potential impact of specialization and in-house management versus procurement of turnkey work |

|

Optimization of purchases taking into account the actual cost of money |

Comparing the cost of your own money with suppliers; Changing the terms of payment: reducing the markup for deferred payment and/or receiving an additional discount that exceeds the cost of money for reducing the payment term; Use of tools: bonds, factoring |

|

Fines, demurrage, etc. |

Calculation of the actual cost of defects, delays in deliveries; Setting penalties (in excess) in contracts with suppliers; Using a bank guarantee |

Release of working capital

The release of working capital accelerates its movement and reduces the need for it in current activities. To achieve this goal, buyers need to pay attention to two main points.

Efficient use of resources. Here the main task is to find rational combinations of raw materials and materials, optimize energy and other costs.

Optimal demand and procurement planning. The efficiency of procurement directly depends on carefully thought-out processes and planning algorithms. In specialized departments, work should be carried out to normalize systems of regulatory and reference information, standardize the equipment used, spare parts and components, plan the purchase of materials necessary in the production process in conjunction with the planning of the production itself. Specific activities in this area are given in Table. 2.

Measures to release working capital (Table 2)

|

Optimization of resource demand planning |

Normalization of reference data; Planning of direct materials in conjunction with production planning; Planning of spare parts and equipment in conjunction with maintenance plans; Planning resource consumption for projects by stages, timely information about project shifts/stops, review of needs, release of unused materials; Determination and reduction of standard replenishment time; Reducing the share of urgent needs; Standardization of equipment, spare parts and components used |

|

Optimization of procurement planning/optimization of inventory levels |

Use of MRP procedures, tools and techniques; Increasing the reliability of information on the levels of warehouse balances, stocks in transit, unmet needs, unfulfilled order balances; Suppression of over-deliveries; Consumption analysis and setting optimal replenishment parameters; Emergency Stock Determination Company; Use of alternative materials; Use of free materials from other production sites; Timely release of unused project reserves; Elimination of “kapterok” and minimization of the range of warehouses at the MOL level in workshops; Use of supplier warehouses (including warehouse store) |

Reducing the cost of the supply function

It is also necessary to optimize the organization of the supply process itself. There are several ways to do this. One of them involves the use of category management procedures, that is, the introduction of a classification of procurement categories by volume, business criticality, availability and complexity of development of alternative suppliers (competition, ability to influence suppliers, availability of standard materials).

For this purpose, you can organize a supply optimization project based on category management.

Transferring procurement to electronic trading platforms, which simplifies the process of preparing procurement documentation, organizing and conducting procedures.

In some cases, it may be necessary to separate the functions of strategic and operational supply. At the same time, it is important to pay attention to the synchronization of production planning, repairs, budgeting and (strategic) procurement processes, as well as long-term contracts.

And some companies may benefit from deciding to outsource some projects or the entire procurement function to an outsourced/shared service center. This will allow the use of VMI technologies, supplier warehouses and will bring a number of other advantages.

The main task of the purchasing department is the organization and implementation of purchasing activities, placement of goods in warehouses, calculation and replenishment of safety stock for all product items. By optimizing this department, it will be possible to free up additional funds by saving on purchasing volumes and minimizing inventories, as well as introducing automated management.

Functional responsibilities of the purchasing department

Before the optimization process, it is necessary to determine the functionality of the purchasing department. This is, first of all, analysis and accounting of goods. A group of managers working on accounting must identify the shortcomings of the existing product procurement system, which leads to a shortage or excess of inventory. Particular attention should be paid to the presence of analogues that can be interchanged. In this case, this leads to a doubling of sales or inventory in warehouses, which significantly distorts the actual amount of inventory and does not allow for correct purchasing.

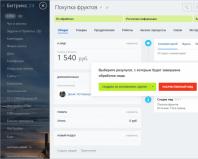

In specialized software, product analysis and analogue accounting can be carried out analytically.

1. Example of accounting for analogues in the Forecast NOW! program:

Analogues are set with one click of the mouse in the program or are automatically downloaded from the user’s accounting system.

After this, the order is calculated only for the main analogue, but the sales history for all similar products is taken into account.

2. Conducting analytics and identifying products with excess (insufficient) stock levels in the Forecast NOW program!

It can be seen that, despite the high sales of flour products, they have the highest minimum balance. Accordingly, this balance can be gradually sold off, and then purchases can be stabilized.

Second example:

The “butter” product group has a fairly high deficit (more than 20%), and the second average sales in the group. Accordingly, it may be worth increasing the level of service for this group.

Thus, the use of software significantly facilitates the work of the procurement department at the stage of analytics and accounting for analogous goods.

The main task of the purchasing department is to calculate purchase volumes. This is done using a calendar plan, which is drawn up taking into account fluctuations in consumer demand for each product item. According to this document, based on the planned need, a plan for purchasing goods is determined. The need can be most accurately calculated using the principles of ABC analysis. For each group of goods, a separate procurement plan is developed, which allows you to plan the flow of finances for a long period.

Using software, you can significantly simplify and make the calculation of purchase volumes more efficient.

1. The program will generate an automatic delivery schedule taking into account delivery times, frequency of orders and other factors.

2. After generating the delivery schedule, the program will accurately calculate the volume of orders. This way your deliveries will be precisely planned.

Example of planned deliveries in the Forecast NOW! program:

Also within the purview of purchasing department managers is the selection of suppliers for each type of product. They submit their proposals to management, which approves the final list. The supplier can be selected on a competitive basis, at thematic exhibitions or on the basis of personal connections. The agreement for the supply of goods is fixed in the form of a contract, which must specify the quantity of goods supplied and the possibility of changing the assortment. In addition, it indicates the frequency of delivery and clarifies logistics issues, as well as provides for penalties for failure to comply with the terms of the contract.

Optimization methods

Optimization of the purchasing department can be done in different ways. One of the most common in large enterprises is the division of functional responsibilities between several departments. Thus, the scope of functional responsibilities of managers is narrowed, which allows them to more effectively solve the tasks assigned to them. At the same time, it is necessary to think through a system of horizontal communication between such departments, otherwise this may lead to confusion during procurement, for example, a situation may arise in the simultaneous purchase of several analogues, which will lead to excess inventory. Or, conversely, managers will not order goods, relying on each other.

Systematic improvement of employee qualifications seems to be a very beneficial method for optimizing the purchasing department. In this case, the funds spent on training are recouped many times over by reducing the number of errors in planning and implementing procurement activities. Here it is necessary to provide for the employee’s contractual obligations to the enterprise, since there is a high probability that a competitor, without investing in staff training, will simply offer a highly qualified employee a higher salary. This will lead to direct and indirect losses (and possibly leakage of proprietary information), and this technique will be ineffective.

Many companies are increasing the number of purchasing department employees. This method of optimizing the purchasing department is effective only up to a certain point. With an excessive increase in the number of employees, the management system is disrupted when functions are duplicated, as a result of which they are performed poorly. At the same time, the cost of the wage fund increases many times over. To avoid this, it is best to create a rigid staffing schedule and strictly adhere to it, adjusting it only if truly necessary.

In modern companies, purchasing departments are equipped with modern software. This really helps optimize their activities, but only if several conditions are met. First of all, you need, with the help of specialists, to select the right program, which is designed specifically for the type of activity that the enterprise is engaged in, and this is a considerable financial investment. At the next stage, you need to account for goods and analyze purchasing activities, which should be entered into the parameters of the procurement automation system. In addition, the issue of training personnel, who must learn to work in new conditions, again arises. If you meet all the requirements and avoid problems that may arise when implementing the software, all costs will be recouped very quickly and the optimization of the purchasing department will be very effective.

The purchasing manager must consider cost trade-offs:

STRATEGY FOR MANAGEMENT OF PURCHASE OF MATERIAL RESOURCES IN AN INDUSTRIAL FIRM

SELECTION OF SUPPLIERS AND CARRIERS

Algorithm for selecting a supplier of material resources (MR):

Evolution of relationships with suppliers:

| Relationship object | Traditional approach | Logistics approach |

| 1. Relationships | Elimination of contradictions | Cooperation |

| 2. Delivery times | Short time | Right on time |

| 3. Supply agreements | Irregular single orders | Long contracts |

| 4. Price | Rate for a one-time agreement (one-time price) | Focus on long-term cooperation |

| 5. Quality | Undefined filters on acceptance | Required (self-certification) |

| 6. Delivery | Rare large lots | Optimal batches |

| 7. Communication channels | Mail, telephone | Modern |

| 8. Interchange | Rare | Affiliate |

The optimization of procurement logistics parameters is based on:

· long-term partnerships for procurement lending;

· internal priorities of production and distribution, search for compromises between various structural divisions of the Company;

· taking into account differences in the supply of products of different nomenclature (assortment) groups:

- goods produced by Aventis AN France, which are delivered to the Company's warehouse according to calculations of needs and sales forecasts provided by the commercial group;

- goods, the need for which arises unexpectedly and do not require long-term storage, are purchased at a time close to their consumption. One-time supplies to meet the needs of the Company’s customers (domestic and foreign goods that expand the standard range);

- regular supplies that are delivered at certain intervals in accordance with the demand schedule (methionine product of Russian production).

SUPPLIER RELATIONSHIP MANAGEMENT

A partnership is a specially built relationship in business, which is based on mutual trust, openness, shared risk and shared reward, which leads to better business results than in the option without forming a partnership.

Types of partnership

Highlight three types of partnership :

Typically, a company has a wide range of relationship types, covering the entire spectrum of options; most of them are not partnerships, but distant associations. Of the relationships classified as partnerships, the majority are Type I partnerships, with only a limited number classified as Type II. Type III partnerships should be established only with those suppliers or customers that are particularly critical to the long-term success of the organization. An example of such a partnership is the interaction option Coca-Cola And McDonald's, which we talked about above.

Partnership model (partnership formation process):

The partnership model shown in the figure has three main elements that provide the parties with the desired result: incentives, supporting factors and components.

Incentives

Both parties must assume that they will receive significant benefits from the partnership and that these benefits cannot be obtained without forming a partnership.

Key incentives (potential benefits):

1) efficient use of assets/costs;

2) improving customer service;

3) marketing benefits;

4) stability/profit growth.

Although strong incentives are necessary for a partnership to be successful, incentives alone do not guarantee success. The benefits obtained from incentives must be sustainable and long-lasting. If the benefits received can easily be duplicated by a rival, the likelihood of success of a long-term partnership is reduced.

How can a manager understand that there are enough incentives for partnership?

1) Such incentives should work in the interests of each party.

2) Incentives must be strong enough to allow each party to have realistic expectations of the benefits to be gained from the partnership, but the strength of specific incentives must be assessed independently by each party.

Supporting factors

Incentives provide the general motivation for creating a partnership. However, even if there is a strong desire to form a partnership, the likelihood of its success will be low if the corporate environment is not conducive to close relationships.

Supporting factors are components of the corporate environment that work for the growth and strengthening of partnerships.

In the short term, supporting factors cannot be developed, i.e. they either exist or they don’t. It is the extent to which they are present that often determines whether a partnership will be successful.

Supporting factors include:

1) consistency at the corporate level;

2) management philosophy and techniques used;

3) reciprocity;

4) symmetry.

Supporting factors should be considered in light of the overall environment in which the two potential partners operate. Therefore, unlike incentives, which are assessed independently by managers of each company, enabling factors must be considered jointly by managers of both companies.

If both partners are realistic about the expected benefits of the collaboration and the corporate environment appears supportive, then the partnership is guaranteed.

At the same time The type of partnership is a function of the combined action of incentives and supporting factors:

It is important to note that in a partnership, bigger is not always better. This means that for any combination of incentives and enabling factors, the goal should not be the establishment of a Type III partnership, but, given the specific incentives and enabling factors at play, the most appropriate type of partnership. Trying to achieve a Type III partnership when incentives and/or supporting factors are weak is more counterproductive than positive, since in this case there is no necessary basis for its creation.

Having determined the type of partnership, it is necessary to actually implement the partnership. This is done through components.

An assessment of incentives and supporting factors is used to determine partnership potential (the type of partnership possible), and component analysis is used to describe the type of relationship that is actually established.

Components

Components are the activities and processes defined and controlled by managers throughout the life of the partnership.

The components make the relationship operational and help managers realize the benefits of the partnership. Every partnership has the same basic components, but the way in which partnerships are implemented and managed varies.

Components include:

1) planning;

2) joint operational control;

3) communications;

4) overall risk and reward;

5) trust and cooperation;

6) style of contracts concluded;

7) scale;

8) financial investments.

Results and feedback

The key to effective measurement and feedback is how well all the incentives of the partnership are taken into account at the outset of its implementation. At this stage, all indicators and metrics for each incentive must be specified explicitly, since then these indicators become standards when assessing the results of the partnership. Feedback can be used at any stage of the model and is carried out in the form of periodic clarification of the status of stimuli, supporting factors and components.

Key results of the partnership include:

1) results from the point of view of a global approach (profit growth, changes in profit over time);

2) process results (improved customer service, reduced costs);

3) competitive advantage (market positioning, market share, access to new knowledge).

STAFF…..

Typical organizational structure:

Division of responsibility for procurement activities:

Procurement activities can be divided into areas for various reasons:

· for large groups of purchased items;

· by products for which the purchased items are used;

· by production stage (for example, raw materials, partially assembled components, fully finished components);

· on the location of enterprises;

Every company accumulates information about procurement: prices, volumes, suppliers. Proper processing of this data allows you to save in ways that many have never dreamed of. I'll tell you how to achieve this.

Keep track of actual prices

If prices have not changed for more than a quarter, there is most likely something wrong with the supplier. In a rare market, nothing happens during this time. The ruble could rise or fall, new raw materials or production technologies could appear. Consequently, the cost of purchases had to change.

Example: The dollar exchange rate in Russia increased, and the supplier increased the cost of packaging materials, and after the ruble strengthened, did not reduce it back. A quarterly analysis of actual prices will help you track stagnation in time and ask for a discount.

It is also worth paying attention to sharp changes in cost within a week or month. Especially if the same product was purchased several times at a price that significantly exceeds the standard price for the analyzed period.

Example: The restaurant was running out of fish, and the supplier did not have the required amount. The buyer ordered it from another partner at a higher price. The company lost money. Regular analysis of actual prices will help avoid such failures.

Conduct independent market monitoring

It will help you understand how much the actual purchase cost of raw materials corresponds to the real one. Perhaps prices have fallen, but the supplier is in no hurry to give a discount, and the buyer is in no hurry to demand.

It is important to compare exactly the price dynamics - an exact comparison may be incorrect due to other delivery conditions and other company quality requirements. Data can be gleaned from industry platform reports.

Example: In one month, the cost of products on the market increased, but the actual price did not. Everything is fine. In another, the price on the market fell, but in the company it rose or remained the same. It is worth understanding the reasons.

Study supplier reports

It is necessary to understand the supplier's place in the value chain. Who is he? Manufacturer, exclusive representative or one of dozens of representatives? The farther from the manufacturer, the higher the purchase price.

Example: A vegetable concentrate plant purchases 1 ton of cucumbers weekly from a wholesale company at 110 rubles per 1 kg. The farm is ready to sell them at 95 rubles per 1 kg. Changing the supplier will help the plant save 60,000 rubles per month, 180,000 rubles per quarter.

Then you should analyze the entire purchased range and identify suppliers who make favorable trade offers for one part of the items, and set unreasonably high prices for the other.

Example: The company quarterly purchases 70 tons of flour from the flour mill at 15 rubles per 1 kg, and, due to the presence of a trading house, 5 tons of sugar at 40 rubles per 1 kg. The manufacturer can supply sugar for 35 rubles per 1 kg. Changing the supplier will save 25,000 rubles per quarter.

Separately, you can consider suppliers with a turnover of up to 50,000 rubles per month and understand whether it makes sense to continue cooperation. The more partners there are, the more time the buyer and accounting department spend on document flow. The company incurs additional costs.

Example: The restaurant chain buys chicken breast weekly: 1.8 tons at 200 rubles per 1 kg from a large supplier and another 500 kg at 220 rubles per 1 kg from a small one. If you transfer the entire volume to one supplier, you will be able to reduce paperwork costs and receive a discount.

Check item reports

It is necessary to determine the principle of volume distribution between suppliers of the same product. It is optimal that the company with the best price provides 70% of the volume, the remaining 30% is supplied by one or two more partners.

Example #1: A meat producer purchases beef tenderloin from three suppliers every month. He orders 700 kg from a farmer at 650 rubles per 1 kg, 160 kg at 665 rubles per 1 kg from a wholesaler, another 140 kg at 680 rubles per 1 kg from another. Great.

Example #2: The company purchases corrugated boxes from three manufacturers every month. 50,000 pieces - 12.9 rubles per unit, 30,000 - 14 rubles per unit, another 20,000 - 12 rubles per unit. It is necessary to identify the reasons for this strange distribution.

Set up deviation reports

They will allow you to receive information about changes in procurement in real time. To do this, you need to determine which deviations in prices or supply volumes are considered acceptable and which are not. Each company will have its own standard.

Example: A manufacturer of canned vegetables purchases 5 tons of tomatoes monthly from two suppliers. The farmer offers low cost, so he supplies 80% of the raw materials. The wholesaler sells at a higher price, his share is 20%. If it increases by 5% in one month, it’s not scary. But if it subsequently increases by another 20% without changing the price, it’s time to talk to the buyer.

Regular analysis of suppliers, product ranges and prices will help directors be confident in the transparency of procurement, make the right management decisions and save millions of rubles every penny.

The main news and the best longreads of “The Secret” are in our Telegram channel. Subscribe!

Cover photo: Sean Gallup/Getty Images