Copper description. Properties of copper - chemical, physical and unique healing

Copper grades are widely represented in various industries: this non-ferrous metal, due to its unique characteristics, is one of the most common. All grades of this metal are distinguished by high ductility and corrosion resistance when used in various environments, with the exception of ammonia and sulfur dioxide gases.

Modern industry produces copper blanks in the form of sheets, pipes, wires, rods and bars. There are oxygen-free (M0) and deoxidized (M1) copper, products from which are widely used in the electrical, electronic and electrovacuum industries. Oxygen-free brands contain O2 within 0.001%, in deoxidized ones - 0.01%.

Today there are quite a lot of grades that are classified according to the purity of the base metal content: M00, M0, M1, M2 and M3. Also common are the M1p, M2p and M3p brands, which are characterized by an oxygen content of 0.01% and phosphorus of 0.04%. For example, grades M1, M2 and M3 contain oxygen in the range of 0.05–0.08%.

| Copper grade | M00 | M0 | M0b | M1 | M1r | M2 | M2r | M3 | M3r | M4 |

|---|---|---|---|---|---|---|---|---|---|---|

| Copper content, % | 99,99 | 99,95 | 99,97 | 99,90 | 99,90 | 99,70 | 99,70 | 99,50 | 99,50 | 99,00 |

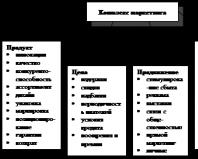

Impurities in copper alloys

Forming solid solutions with copperSuch impurities include aluminum, antimony, nickel, iron, tin, zinc, etc. These additives significantly reduce electrical and thermal conductivity. The grades that are primarily used for the production of conductive elements include M0 and M1. If the copper alloy contains antimony, its hot pressure treatment becomes significantly more difficult.

Impurities that do not dissolve in copperThese include lead, bismuth, etc. Although they do not affect the electrical conductivity of the base metal, such impurities make it difficult to process by pressure.

Impurities that form brittle chemical compounds with copperThis group includes sulfur and oxygen, which reduces the electrical conductivity and strength of the base metal. The sulfur content of the copper alloy greatly facilitates its machinability by cutting.

Standards for Copper Alloys

State standards stipulate the rules for marking copper and its alloys, the designation of which corresponds to a certain structure.

The fact that this is one of the copper grades is indicated by the letter “M” in its designation. After the initial letter in the marking of copper and its alloys there are numbers (from 0 to 3), conventionally indicating the mass fraction of the base metal in their composition (for example, M3 copper). The numbers are followed by capital letters, by which you can determine how this grade of copper was obtained. The following technological methods are distinguished:

- cathode (k);

- deoxidation method, which assumes a low content of residual phosphorus (p);

- deoxidation method, which assumes a high content of residual phosphorus (f);

- without the use of deoxidizers - oxygen-free (b).

Examples of markings for such brands may look like this: M2p, M1b.

A number of copper grades, distinguished by unique characteristics, are actively used in various industries.

- M0 - this grade is used for the production of conductive elements and for adding to alloys of high purity.

- M1 - this grade is also used to produce conductive elements, rolled products of various profiles, bronze, parts for cryogenic equipment, electrodes for, wire and rods (used for making in inert gases), consumables for making copper parts that do not experience significant loads during operation.

- M2 - this brand allows you to obtain products that can be easily processed by pressure. M2 copper is also used for cryogenic equipment parts.

- MZ - parts from this grade of metal are produced by the rolling method.

GOST 859-2001, which specified the requirements and characteristics of copper alloys, was replaced in 2014 by a new state standard (859-2014), which was recorded by the corresponding Order of the Federal Agency for Technical Regulation and Metrology. The new standard in its main points is almost identical to GOST 859-2001.

GOST 859-2001 on copper grades

This state standard document applies to cast and deformed semi-finished copper products, as well as copper manufactured in the form of cathodes.

In D.I. Mendeleev’s periodic system of elements, copper is located in group I of the 4th period, its serial number is 29. Atomic mass is 63.54. As an element of the first group, copper is monovalent. In this state, it is widely represented in ore minerals, mattes, slags and other products of pyrometallurgy. In the products of their oxidation in nature and in technological processes, the divalent state is more stable.

The melting point of copper is 1083 0 C. The boiling point is 2325 0 C.

Copper is a soft, viscous and malleable metal of red color, easy to machine. Easily rolled into thin sheets and drawn into wire.

The most important property is electrical conductivity (second only to silver). Impurities reduce electrical conductivity, so high-purity copper is used in electrical engineering.

Copper also has high thermal conductivity.

Chemically, copper is inactive, although it can directly combine with oxygen, sulfur, halogens and some other elements.

At normal temperatures and dry air, copper remains inert, but in humid air containing CO 2, copper oxidizes and becomes covered with a protective film of basic carbonate CuCO 3 ·Cu(OH) 2, which is a toxic substance.

Copper does not dissolve in solutions of hydrochloric and sulfuric acids in the absence of an oxidizing agent. In acids that are also oxidizing agents (nitric or hot concentrated sulfuric acid), copper dissolves easily.

At high temperatures in pyrometallurgical processes, stable copper compounds are Cu 2 O and Cu 2 S.

Copper and its sulfide Cu 2 S are good collectors (solvents) of gold and silver, which makes their high associated recovery possible in copper production.

An important property of copper is to form alloys with other metals. These are bronze (Cu + Sn), brass (Cu + Zn) and copper-nickel alloys.

In modern bronzes, aluminum, silicon, beryllium, and lead are used as additives. These bronzes are used for the manufacture of critical parts and cast products.

For example, beryllium bronzes (2% Be) are superior in mechanical properties to many types of steel and have good electrical conductivity. Aluminum bronzes (5-10% Al) are very durable and are used in the manufacture of aircraft engines.

In addition to zinc, aluminum, iron, silicon, and nickel are added to special brasses. Brass is used to make radiators, pipes, flexible hoses, cartridge cases, and art products.

Of the copper-nickel alloys, the most famous are cupronickel (used in shipbuilding, as it is resistant to sea water) and nickel silver - resistant to solutions of salts and organic acids (medical instruments are made).

About 50% of all copper is used by the electrical industry. Copper is also used in mechanical engineering, rocketry, in the production of building materials, in transport, the chemical industry, and agriculture.

1.3 Raw materials for copper production

Clark copper, i.e. its content in the earth's crust is 0.01%. However, it forms numerous deposits. Copper is characterized by the presence of all 4 types of ores in nature. However, the main copper raw materials are sulfide ores. Currently, 85-90% of all primary copper is smelted from sulfide ores.

In Russia, copper ores are mined in the Urals - Kirovgrad, Krasnouralsk, Mednogorsk, Gai, etc., in the Arctic - on the Kola Peninsula and Taimyr.

The sources of copper are ores, their enrichment products - concentrates - and secondary raw materials. Recycled raw materials currently account for about 40% of total copper output.

Copper ores are almost entirely polymetallic. There are no monometallic ores of copper in nature. About 30 elements are valuable companions of copper in ore raw materials. The most important of them are: zinc, lead, nickel, cobalt, gold, silver, platinum group metals, sulfur, selenium, tellurium, cadmium, germanium, rhenium, indium, thallium, molybdenum, iron.

More than 250 copper minerals are known. Most of them are rare. A small group of minerals, the composition of which is given in Table 2, is of greatest industrial importance.

Table 2 - Industrial copper minerals

|

chemical | ||

|

Sulfide minerals |

||

|

chalcopyrite | ||

|

covelline | ||

|

chalcocite | ||

|

Oxidizedminerals |

||

|

CuCO 3 Cu(OH) 2 | ||

|

CuCO 3 2Cu(OH) 2 | ||

|

chrysocolla |

CuSiO 3 2H 2 O | |

|

native copper |

Cu, Ag, Au, Fe, Bi, etc. | |

Most copper ores are currently mined by open-pit mining. In Russia, the share of underground mining accounts for about 30%.

In modern practice, ores are usually developed with a copper content of 0.8-1.5%, sometimes higher. But for large deposits of disseminated ores, the minimum copper content suitable for development is 0.4-0.5%. If the rock contains less than the specified amount of copper, its processing is unprofitable.

The value of copper ores increases significantly due to the presence of noble metals and a number of rare metals - selenium, tellurium, rhenium, bismuth, etc.

Due to the low copper content in the ore and the complex nature of the ores, the raw materials are preliminarily subjected to flotation concentration. When beneficiating copper ores, the main product is copper concentrates containing up to 55% Cu (usually 10-30%). Pyrite concentrates and concentrates of other non-ferrous metals, such as zinc, are also obtained. Flotation concentrates are fine powders with particles of 74 microns and a moisture content of 8-10%.

Copper ores and concentrates have the same mineralogical composition and differ only in the quantitative relationships between various minerals. The physical and chemical bases of their metallurgical processing are exactly the same.

- Designation - Cu (Copper);

- Period - IV;

- Group - 11 (Ib);

- Atomic mass - 63.546;

- Atomic number - 29;

- Atomic radius = 128 pm;

- Covalent radius = 117 pm;

- Electron distribution - 1s 2 2s 2 2p 6 3s 2 3p 6 3d 10 4s 1 ;

- melting temperature = 1083.4°C;

- boiling point = 2567°C;

- Electronegativity (according to Pauling/according to Alpred and Rochow) = 1.90/1.75;

- Oxidation state: +3, +2, +1, 0;

- Density (no.) = 8.92 g/cm3;

- Molar volume = 7.1 cm 3 /mol.

Copper (cuprum, got its name in honor of the island of Cyprus, where a large copper deposit was discovered) is one of the first metals that man mastered - the Copper Age (the era when copper tools predominated in human use) covers the period of the 4th-3rd millennium BC . e.

An alloy of copper and tin (bronze) was obtained in the Middle East 3000 BC. e. Bronze was preferred to copper because it was stronger and easier to forge.

Rice. Structure of the copper atom.

The electronic configuration of the copper atom is 1s 2 2s 2 2p 6 3s 2 3p 6 3d 10 4s 1 (see Electronic structure of atoms). In copper, one paired electron from the outer s-level “jumps” to the d-sublevel of the outer orbital, which is associated with the high stability of the completely filled d-level. The completed stable d-sublevel of copper determines its relative chemical inertness (copper does not react with hydrogen, nitrogen, carbon, or silicon). Copper in compounds can exhibit oxidation states +3, +2, +1 (the most stable are +1 and +2).

Rice. Electronic configuration of copper.

Physical properties of copper:

- metal, red-pink color;

- has high malleability and ductility;

- good electrical conductivity;

- low electrical resistance.

Chemical properties of copper

- When heated, it reacts with oxygen:

O 2 + 2Cu = 2CuO; - when exposed to air for a long time, it reacts with oxygen even at room temperature:

O 2 + 2Cu + CO 2 + H 2 O = Cu(OH) 2 CuCO 3 ; - reacts with nitric and concentrated sulfuric acid:

Cu + 2H 2 SO 4 = CuSO 4 + SO 2 + 2H 2 O; - Copper does not react with water, alkali solutions, hydrochloric and dilute sulfuric acid.

Copper connections

Copper oxide CuO(II):

- a red-brown solid, insoluble in water, exhibits basic properties;

- when heated in the presence of reducing agents, it gives free copper:

CuO + H 2 = Cu + H 2 O; - Copper oxide is produced by the reaction of copper with oxygen or the decomposition of copper (II) hydroxide:

O 2 + 2Cu = 2CuO; Cu(OH) 2 = CuO + H 2 O.

Copper hydroxide Cu(OH 2)(II)):

- crystalline or amorphous substance of blue color, insoluble in water;

- decomposes into water and copper oxide when heated;

- reacts with acids to form the corresponding salts:

Cu(OH 2) + H 2 SO 4 = CuSO 4 + 2H 2 O; - reacts with alkali solutions, forming cuprates - complex compounds of bright blue color:

Cu(OH 2) + 2KOH = K 2.

For more information on copper compounds, see Copper oxides.

Production and use of copper

- Using the pyrometallurgical method, copper is obtained from sulfide ores at high temperatures:

CuFeS 2 + O 2 + SiO 2 → Cu + FeSiO 3 + SO 2; - Copper oxide is reduced to copper metal by hydrogen, carbon monoxide, and active metals:

Cu 2 O + H 2 = 2Cu + H 2 O;

Cu 2 O + CO = 2Cu + CO 2;

Cu 2 O + Mg = 2Cu + MgO.

The use of copper is determined by its high electrical and thermal conductivity, as well as ductility:

- production of electrical wires and cables;

- in heat exchange equipment;

- in metallurgy to produce alloys: bronze, brass, cupronickel;

- in radio electronics.

A mineral from the class of native elements. Fe, Ag, Au, As and other elements are found in natural minerals as impurities or forming solid solutions with Cu. The simple substance copper is a ductile transition metal of golden-pink color (pink in the absence of an oxide film). One of the first metals widely mastered by man due to its relative availability for extraction from ore and low melting point. It is one of the seven metals known to man since very ancient times. Copper is an essential element for all higher plants and animals.

See also:

STRUCTURE

Cubic system, hexaoctahedral type of m3m symmetry, crystal structure - cubic face-centered lattice. The model is a cube of eight atoms in the corners and six atoms located in the center of the faces (6 faces). Each atom of a given crystal lattice has a coordination number of 12. Native copper occurs in the form of plates, spongy and solid masses, thread-like and wire-like aggregates, as well as crystals, complex twins, skeletal crystals and dendrites. The surface is often covered with films of “copper green” (malachite), “copper blue” (azurite), copper phosphates and other products of its secondary alteration.

PROPERTIES

Copper is a golden-pink ductile metal; in air it quickly becomes covered with an oxide film, which gives it a characteristic intense yellowish-red hue. Thin films of copper have a greenish-blue color when exposed to light.

Along with osmium, cesium and gold, copper is one of the four metals that have a distinct color color that is different from the gray or silver of other metals. This color tint is explained by the presence of electronic transitions between the filled third and half-empty fourth atomic orbitals: the energy difference between them corresponds to the wavelength of orange light. The same mechanism is responsible for the characteristic color of gold.

Copper has high thermal and electrical conductivity (it ranks second in electrical conductivity among metals after silver). Specific electrical conductivity at 20 °C: 55.5-58 MS/m. Copper has a relatively large temperature coefficient of resistance: 0.4%/°C and is weakly dependent on temperature over a wide temperature range. Copper is diamagnetic.

There are a number of copper alloys: brass - with zinc, bronze - with tin and other elements, cupronickel - with nickel and others.

RESERVES AND PRODUCTION

The average copper content in the earth's crust (clarke) is (4.7-5.5)·10−3% (by mass). In sea and river water the copper content is much lower: 3·10−7% and 10−7% (by mass), respectively. Most copper ore is mined by open pit mining. The copper content in the ore ranges from 0.3 to 1.0%. World reserves in 2000 were, according to experts, 954 million tons, of which 687 million tons were proven reserves; Russia accounted for 3.2% of total and 3.1% of confirmed world reserves. Thus, at the current rate of consumption, copper reserves will last approximately 60 years.

Copper is obtained from copper ores and minerals. The main methods for obtaining copper are pyrometallurgy, hydrometallurgy and electrolysis. The pyrometallurgical method consists of obtaining copper from sulfide ores, for example, chalcopyrite CuFeS 2. The hydrometallurgical method involves dissolving copper minerals in dilute sulfuric acid or ammonia solution; From the resulting solutions, copper is replaced by metallic iron.

ORIGIN

Small nugget of copper

Typically, native copper is formed in the oxidation zone of some copper sulfide deposits in association with calcite, native silver, cuprite, malachite, azurite, brochantite and other minerals. The masses of individual clusters of native copper reach 400 tons. Large industrial deposits of native copper, along with other copper-containing minerals, are formed when volcanic rocks (diabases, melaphyres) are exposed to hydrothermal solutions, volcanic vapors and gases enriched in volatile copper compounds (for example, the Lake Superior deposit, USA).

Native copper is also found in sedimentary rocks, mainly in cuprous sandstones and shales.

The most famous deposits of native copper are the Turin mines (Urals), Dzhezkazgan (Kazakhstan), in the USA (on the Keweenaw Peninsula, in the states of Arizona and Utah).

APPLICATION

Due to its low resistivity, copper is widely used in electrical engineering for the manufacture of power cables, wires or other conductors, for example, in printed circuit wiring. Copper wires, in turn, are also used in the windings of energy-saving electric drives and power transformers.

Another useful quality of copper is its high thermal conductivity. This allows it to be used in various heat removal devices and heat exchangers, which include well-known radiators for cooling, air conditioning and heating.

Alloys using copper are widely used in various fields of technology, the most widespread of which are the above-mentioned bronze and brass. Both alloys are general names for a whole family of materials, which in addition to tin and zinc may include nickel, bismuth and other metals.

In jewelry, alloys of copper and gold are often used to increase the resistance of products to deformation and abrasion, since pure gold is a very soft metal and is not resistant to these mechanical influences.

The predicted new mass use of copper promises to be its use as bactericidal surfaces in medical institutions to reduce intra-hospital bacterial transfer: doors, handles, water stop valves, railings, bed rails, tabletops - all surfaces touched by the human hand.

Copper - Cu

CLASSIFICATION

Hey's CIM Ref1.1

| Strunz (8th edition) | 1/A.01-10 |

| Nickel-Strunz (10th edition) | 1.AA.05 |

| Dana (7th edition) | 1.1.1.3 |

| Dana (8th edition) | 1.1.1.3 |

Most industrial sectors use a metal such as copper. Due to its high electrical conductivity, not a single area of electrical engineering can do without this material. It produces conductors with excellent performance characteristics. In addition to these features, copper has ductility and refractoriness, resistance to corrosion and aggressive environments. And today we will look at the metal from all sides: we will indicate the price for 1 kg of scrap copper, we will tell you about its use and production.

Concept and features

Copper is a chemical element belonging to the first group of the Mendeleev periodic table. This ductile metal has a golden-pink color and is one of three metals with a distinct color. Since ancient times, it has been actively used by man in many areas of industry.

The main feature of the metal is its high electrical and thermal conductivity. When compared with other metals, the conductivity of electric current through copper is 1.7 times higher than that of aluminum, and almost 6 times higher than that of iron.

Copper has a number of distinctive features over other metals:

- Plastic. Copper is a soft and ductile metal. If you take copper wire into account, it bends easily, takes any position and does not deform. It is enough to press the metal itself a little to check this feature.

- Corrosion resistance. This photosensitive material is highly resistant to corrosion. If copper is left in a humid environment for a long time, a green film will begin to appear on its surface, which protects the metal from the negative effects of moisture.

- Response to temperature rise. You can distinguish copper from other metals by heating it. In the process, the copper will begin to lose its color and then become darker. As a result, when the metal is heated, it will turn black.

Thanks to such features, it is possible to distinguish this material from and other metals.

The video below will tell you about the beneficial properties of copper:

Advantages and disadvantages

The advantages of this metal are:

- High thermal conductivity;

- Resistance to corrosion;

- Quite high strength;

- High plasticity, which is maintained up to a temperature of -269 degrees;

- Good electrical conductivity;

- Possibility of alloying with various additional components.

Read below about the characteristics, physical and chemical properties of the metal substance copper and its alloys.

Properties and characteristics

Copper, as a low-active metal, does not interact with water, salts, alkalis, or weak sulfuric acid, but is subject to dissolution in concentrated sulfuric and nitric acid.

Physical properties of metal:

- The melting point of copper is 1084°C;

- The boiling point of copper is 2560°C;

- Density 8890 kg/m³;

- Electrical conductivity 58 MOhm/m;

- Thermal conductivity 390 m*K.

Mechanical properties:

- The tensile strength in the deformed state is 350-450 MPa, in the annealed state - 220-250 MPa;

- Relative narrowing in the deformed state is 40-60%, in the annealed state – 70-80%;

- The relative elongation in the deformed state is 5-6 δ ψ%, in the annealed state – 45-50 δ ψ%;

- The hardness in the deformed state is 90-110 HB, in the annealed state - 35-55 HB.

At temperatures below 0°C this material has higher strength and ductility than at +20°C.

Structure and compound

Copper, which has a high electrical conductivity coefficient, has the lowest impurity content. Their share in the composition can be equal to 0.1%. In order to increase the strength of copper, various impurities are added to it: antimony, etc. Depending on its composition and the degree of pure copper content, several grades are distinguished.

The structural type of copper may also include crystals of silver, calcium, aluminum, gold and other components. All of them are characterized by comparative softness and plasticity. The copper particle itself has a cubic shape, the atoms of which are located at the vertices of the F-cell. Each cell consists of 4 atoms.

To learn where to get copper, watch this video:

Production of materials

Under natural conditions, this metal is found in native copper and sulfide ores. Ores called “copper luster” and “copper pyrite”, which contain up to 2% of the required component, are widely used in the production of copper.

Most (up to 90%) of the primary metal is due to the pyrometallurgical method, which includes a lot of stages: beneficiation process, roasting, smelting, processing in a converter and refining. The remaining part is obtained by the hydrometallurgical method, which consists of leaching it with diluted sulfuric acid.

Areas of use

in the following areas:

in the following areas:

- Electrical industry, which consists primarily in the production of electrical wires. For these purposes, copper must be as pure as possible, without foreign impurities.

- Making filigree products. Copper wire in the annealed state is characterized by high ductility and strength. That is why it is actively used in the production of various cords, ornaments and other designs.

- Melting copper cathode into wire. A wide variety of copper products are melted down into ingots, which are ideal for further rolling.

Copper is actively used in a wide variety of industries. It can be part of not only wire, but also weapons and even jewelry. Its properties and wide scope of application have favorably influenced its popularity.

The video below explains how copper can change its properties: