Job description for physical and mechanical testing laboratory assistant. Laboratory assistant training for physical and mechanical testing

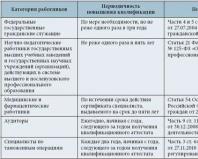

The profession of physical and mechanical testing laboratory assistant is quite in demand and promising today. New modern laboratories are opening, with the latest equipment, which requires qualified personnel for research and work. An important condition is the availability of professional education. Enterprise managers are required to regularly send employees to special training courses to learn how to work with new equipment and improve staff qualifications.

The Interregional Training Center guarantees high-quality training and retraining of specialists in the profession of physical and mechanical testing laboratory assistant. All modern, proven training programs and materials are used for training.

The purpose of the training is to train or retrain specialists, obtain new theoretical knowledge and practical skills in working with modern laboratory equipment. The training course includes a large number of practical exercises and consultations to gain in-depth knowledge. The teaching staff closely monitors changes in legislation and promptly responds to them with changes in the curriculum. Thus, guaranteeing a high-quality level of training, taking into account the specifics and areas of activity.

Distance learning is possible, without interruption from the main activity. To register for courses, leave a request on our website.

Our advantages:

- Five years of successful operation of the training center guarantee a professional approach and a high-quality training program;

- License for vocational training issued by the Moscow Department of Education;

- Experienced teaching staff;

- A specially equipped classroom for practical training;

- Quality knowledge is guaranteed at reasonable prices.

Studying time:

Contact us and your application will be reviewed instantly!

The issue was approved by Resolution of the USSR State Committee on Labor and Social Issues and the Secretariat of the All-Union Central Council of Trade Unions dated January 31, 1985 N 31/3-30

(as amended:

Resolutions of the State Labor Committee of the USSR, the Secretariat of the All-Union Central Council of Trade Unions dated 10/12/1987 N 618/28-99, dated 12/18/1989 N 416/25-35, dated 05/15/1990 N 195/7-72, dated 06/22/1990 N 248/10-28,

Resolutions of the State Committee for Labor of the USSR 12/18/1990 N 451,

Resolutions of the Ministry of Labor of the Russian Federation dated December 24, 1992 N 60, dated 02/11/1993 N 23, dated 07/19/1993 N 140, dated 06/29/1995 N 36, dated 06/01/1998 N 20, dated 05/17/2001 N 40,

Orders of the Ministry of Health and Social Development of the Russian Federation dated July 31, 2007 N 497, dated October 20, 2008 N 577, dated April 17, 2009 N 199)

Laboratory assistant for physical and mechanical testing

§ 120. Laboratory assistant for physical and mechanical tests (2nd category)

Characteristics of work. Physico-mechanical tests of metals, raw materials, products, alloys, various materials, semi-finished and finished products for strength, tensile, bending, heat resistance, compression, removal and pushing force, rupture, hardness, air tightness, viscosity, flouriness, twisting, thickness, humidity , water resistance, grease content and other quality indicators on control and testing installations, on Rockwell, Brinell instruments, etc. in accordance with current instructions. Measurement of electrical resistance by the bridge method and the ampere-voltmeter method. Determination of density by hydrostatic weighing. Checking the cell sizes and the density of nodes and connections. Determination of the percentage of shrinkage and adhesion. Maintaining established test control records. Preparation and degreasing of sample samples for testing. Selection and preparation of instruments and apparatus for testing. Adjustment of instruments and devices under the guidance of a more highly qualified laboratory assistant. Preparation of developer and fixer according to a given recipe, processing of photographic paper, film and plates, making prints from photographic negatives.

Must know: classification of physical and mechanical tests; basic physical and mechanical properties of the tested metals and materials; basic information about the electrical properties of metals and non-metallic materials; electrical resistivity; methods for determining electrolyte density; methods for preparing samples for testing; basics of electrical engineering within the scope of the work performed; rules for storing and using photographic materials: chemical reagents, photographic paper, photographic plates; methods for preparing developer and fixer according to recipe; the procedure for selecting and processing samples according to the types and properties of the analyzed materials, raw materials, semi-finished products and finished products; the operating principle of the equipment being serviced and the rules for handling it during analysis and testing; test results recording system; state standards and technical conditions for testing; purpose of control and measuring instruments, tools and rules for their use.

§ 121. Laboratory assistant for physical and mechanical tests (3rd category)

Characteristics of work. Physical and mechanical tests of raw materials, materials, semi-finished products and finished products with the performance of work on processing and summarizing the results of the tests. Performing calculations to determine quality indicators of materials, raw materials, semi-finished products and finished products. Determination of compliance of tested samples with state standards and technical specifications. Preparation of prototypes in laboratory conditions. Determination of grinding fineness, uniformity of volume change, setting time and volumetric mass of materials. Calculation of load values based on sample sizes. Determination of temperatures using thermocouples when testing samples for heat resistance. Mounting the thermocouple. Correcting for cold junction temperature. Determination of the normal elastic modulus and shear modulus by radio engineering method, standardization of the installation for determining the moduli. Measuring magnetic permeability on a ballistic installation. Making corrections for the geometric dimensions of the sample. Regulating the uniformity of heating of the sample along its length, controlling the heating temperature with thermocouples. Measurement with a thermocouple vacuum gauge of vacuum up to 174 - 1.3 Pa (up to 1.31 - 10 mm Hg). Changing the oil in the fore-vacuum pump. Checking and adjusting laboratory equipment during testing. Monitoring the passage of a pilot batch of raw materials, materials and semi-finished products in production. Graphic representation of test results.

Must know: arrangement of serviced equipment; recipe, types, purpose and characteristics of materials, raw materials, semi-finished products and finished products to be tested; rules for conducting physical and mechanical tests of varying complexity with performing work on their processing and generalization; the principle of operation of ballistic installations for determining magnetic permeability; main components of vacuum systems of fore-vacuum and diffusion pumps, thermocouple vacuum gauge; basic methods for determining the physical properties of samples; basic properties of magnetic bodies; thermal expansion of alloys; a method for determining the coefficients of linear expansion of critical points on dilatometers; a technique for determining temperature using high- and low-temperature thermometers; elastic properties of metals and alloys; rules for making corrections to the geometric dimensions of the sample; graphing methods; a system of recording tests performed and a methodology for summarizing test results.

§ 122. Laboratory assistant for physical and mechanical tests (4th category)

Characteristics of work. Determination of magnetic susceptibility, magnetic permeability, residual induction, coercive force. Removing the hysteresis loop on the permeameter. Checking the wire for homogeneity and thermoelectromotive force with standards. Temperature control of cold junctions of thermocouples. Recording thermal cycles of sample cooling and heating. Creation of high vacuum in installations, measuring it with vacuum gauges. Determination of thermal conductivity, heat capacity and electrical conductivity. Determination of thermal expansion coefficients and critical points using a vacuum dilatometer. Adjustment of used devices and their settings. Determination of the yield strength of a metal from a diagram. Drawing up calculation tables. Calibration of thermocouples and dilatometers for the production and refinement of temperature scales. Measuring soil temperature with mercury inertial thermometers. Carrying out control tests. Working with light beam oscilloscopes. Selecting the required vibrator, installing it in a magnetic block. Calculation of residual stresses using the ring method based on these measurements. Adjustment of the optical system and oscilloscope timer. Oscillogram processing.

Must know: construction of permeameters, installations for determining the magnetic properties of metals in constant magnetic fields, potentiometers for temperature control, installations for determining thermal conductivity, heat capacity and electrical conductivity, light-beam oscilloscopes, ionization and magnetic discharge manometers; ferro-, dia- and paramagnetic materials; dependence of magnetic permeability on field; basic methods for determining magnetic properties; methods of working on a permeameter, ferrotester, installation for determining magnetic susceptibility; fundamentals of materials science; high vacuum measurement methods; methods for identifying leaks and eliminating them; thermal properties of metals and alloys; methods for determining thermal conductivity and heat capacity; fundamentals of metallurgy and heat treatment; the magnitude of permissible loads and stresses on the material being tested; strength and yield limits in tension and bending, fatigue limits, maximum stresses.

§ 123. Laboratory assistant for physical and mechanical tests (5th category)

Characteristics of work. Physical and mechanical tests of all types of welded joints, pipes of various diameters, sheet and profile products to obtain all characteristics in accordance with technical requirements and conditions. Conducting various non-standard tests. Testing of finished units, products and chains, calibration of special devices adjustable for torque. Assembly of circuits and instruments for non-standard tests. Calibration of recording and recording equipment. Carrying out tests using various strain gauges. Recording decomposition curves and supercooled austenite on an anisometer and temperature curves during the manufacture of control thermocouples. Determination of linear expansion coefficients on automatic high-temperature dilatometers. Determination of the thermal properties of substances using a calorimeter with electronic heating. Determination of the attenuation decrement of samples in the low frequency range. Determination of the purity of metals after zone melting by measuring residual resistance at liquid helium temperature. Filling vessels with compressed and liquefied gases. Carrying out routine repairs and adjustments of used equipment.

Must know: methodology for conducting mechanical tests of various welds, pipes, rolled products, finished components and products; principle of calculation and drawing up diagrams for non-standard tests; arrangement of light beam oscilloscopes, strain gauges and strain gauge equipment; installation of automatic high-temperature dilatometers, installations for determining internal friction in metals, calorimeters, various types of installations for determining the residual electrical resistance of metals and alloys, anisometers; basics of dilatometry within the scope of work performed; iron carbon phase diagram; the influence of alloying elements on the physical properties of metals and alloys; a method for determining thermal expansion on high-temperature dilatometers in an environment of inert gases; rules for drawing diagrams of isothermal decomposition of supercooled austenite at low and high temperatures when using a bath of liquid nitrogen, oil and liquid tin; properties of materials at low temperatures; properties of liquefied gases; method for determining residual electrical resistance; mathematical processing of experimental data; rules for working with liquid nitrogen; method for determining the physical properties of materials.

§ 124. Laboratory assistant for physical and mechanical tests (6th category)

Characteristics of work. Conducting physical and mechanical tests to determine electrical conductivity and temperature coefficient of resistance in micron-section samples of increased complexity. Removing thermokinematic curves on an anisometer and dilatometer at temperatures from -196 degrees. C and above. Determination of the thermal properties of substances by electron bombardment. Turning on, servicing and turning off high temperature heaters. Measurement of electrical conductivity, thermal conductivity, thermal expansion coefficient, emissivity coefficient at high temperatures in vacuum and inert media. Characterization of thermoelectrode materials at cryogenic temperatures. Determination of the attenuation decrement in the region of high frequencies and high temperatures. Participation in the development of methods for new alloys and metrological certification of installations.

Must know: principles of high temperature heating; dependence of heating temperature on power consumption; materials for high temperature heaters; the role of heat shields; the principle of heating substances by electron bombardment; the basic laws of electron heating and temperature distribution over a sample when it is bombarded with electrons; methods for determining the physical properties of materials at temperatures above 1000 degrees. C; methods for measuring high temperatures using reference pyrometers; methods for calibrating thermocouples using reference pyrometers; features of the design of high-temperature installations; ways to reduce heat loss; methods for accounting for heat loss and introducing corrections for heat loss during mathematical processing of measurement results.

Secondary specialized education required.

Examination tickets comply with Order of the Ministry of Education and Science of Russia dated August 2, 2013 N 915 “On approval of the federal state educational standard for secondary vocational education in the profession 240100.01 Laboratory assistant for physical and mechanical testing” (Registered with the Ministry of Justice of Russia on August 20, 2013 N 29491)

Examination tickets for Laboratory Assistant for physical and mechanical testing contain references in the normative and technical literature to the correct answers, which allows you to quickly and efficiently prepare for certification

IV. CHARACTERISTICS OF PROFESSIONAL

ALUMNI ACTIVITIES

4.1. Area of professional activity of graduates: physical and mechanical testing of raw materials, materials, semi-finished products and finished products in various sectors of the economy.

4.2. The objects of professional activity of graduates are:

raw materials and materials;

finished products and semi-finished products;

laboratory equipment;

instruments and test benches;

regulatory and technical documentation.

4.3. A student trained in profession 240100.01 Physico-mechanical testing laboratory assistant prepares for the following types of activities:

4.3.1. Preparation of samples for testing.

4.3.2. Preparation of equipment for physical and mechanical tests.

4.3.3. Performing physical and mechanical tests on laboratory equipment.

4.3.4. Compliance with safety rules and practices, industrial sanitation and fire safety.

5.2. A graduate who has mastered PPKRS must have professional competencies corresponding to the following types of activities:

5.2.1. Preparation of samples for testing.

PC 1.1. Make prototypes in laboratory conditions.

PC 1.2. Determine the compliance of the parameters of the tested samples with GOST and TU.

5.2.2. Preparation of equipment for physical and mechanical tests.

PC 2.1. Inspect laboratory equipment.

PC 2.2. Perform simple adjustments of laboratory equipment.

PC 2.3. Perform equipment adjustment work.

5.2.3. Performing physical and mechanical tests on laboratory equipment.

PC 3.1. Start and stop laboratory equipment.

PC 3.2. Observe the operation of equipment during testing.

PC 3.3. Take readings from instruments.

PC 3.4. Perform calculations and graphic work related to the tests being carried out.

PC 3.5. Prepare reports on the work done.

5.2.4. Compliance with safety rules and practices, industrial sanitation and fire safety.

PC 4.1. Be familiar with safety procedures when conducting tests.

PC 4.2. Use primary fire extinguishing agents.

PC 4.3. Provide first aid to the victim.

Course topics:

Topic 1 General professional educational cycle

As a result of studying the mandatory part of the educational cycle, a student in general professional disciplines must:

control the implementation of grounding and zeroing;

start and stop electric motors installed on the equipment being operated;

take operating readings and use electrical equipment in compliance with safety standards and operating rules;

basic concepts about direct and alternating electric current, series and parallel connection of conductors and current sources, units of measurement of current, voltage, electric current power, conductor resistance, electric and magnetic fields;

the essence and methods of measuring electrical quantities, design and technical characteristics of measuring instruments;

basic laws of electrical engineering;

rules for graphic representation and drawing up electrical diagrams;

symbols of electrical devices and electrical machines;

main elements of electrical networks;

principles of operation, design, basic characteristics of electrical measuring instruments, electrical machines, control and protection equipment, power supply circuits;

DC and AC motors, their structure, principle of operation, starting and stopping rules;

safety rules when working with electrical devices OP.01.

Topic 2 Technical drawing

general information about assembly drawings, the purpose of conventions and simplifications used in drawings, rules for preparing and reading working drawings;

main provisions of design, technological and other regulatory documentation;

geometric constructions and rules for drawing technical details, methods of graphical representation of technological equipment and execution of technological diagrams;

requirements of ESKD and ESTD standards for the design and preparation of drawings and diagrams

Topic 3 Fundamentals of materials science and technology of general metalwork

determine the properties and classify materials used in production according to composition, purpose and method of preparation;

select basic structural materials with similar thermal expansion coefficients;

perform general metalwork work: marking, cutting, straightening, bending, cutting, filing, scraping metal, drilling, countersinking and reaming holes, riveting, soldering, tinning and gluing, threading;

use tools and instrumentation when performing plumbing work;

basic information about the purpose and properties of metals and alloys, about the technology of their production;

main types, properties and areas of application of structural metal and non-metallic materials used in production;

structural features of metals and alloys;

types of gasket and sealing materials;

classification and properties of metals and alloys, basic protective materials, composite materials;

types of mechanical, chemical and thermal processing of metals and alloys;

methods for measuring parameters and determining properties of materials;

basic information about crystallization and structure of melts;

basic properties of polymers and their use; methods of heat treatment and protection of metals from corrosion;

types of plumbing work and technology for their implementation;

device, purpose, rules for the selection and use of tools and instrumentation used in plumbing work;

requirements for the quality of processing of parts;

types of wear of parts and assemblies;

properties of lubricants

Topic 4 Fundamentals of technical mechanics

method for calculating structural elements for strength, rigidity and stability under various types of deformation OP.04.

assemble structures from parts according to drawings and diagrams;

determine stresses in structural elements;

types of wear and deformation of parts and assemblies;

types of lubricants, requirements for the properties of oils used to lubricate components and parts, rules for storing lubricants;

kinematics of mechanisms, connections of machine parts, mechanical transmissions, types and design of transmissions;

purpose and classification of bearings;

main types of lubrication devices;

types, purpose, design of gearboxes;

friction, its types, the role of friction in technology;

design and purpose of tools and instrumentation used in the maintenance and repair of equipment;

methodology for calculating structural elements for strength, rigidity and stability under various types of deformation

Topic 5 Occupational safety

use personal and group protective equipment;

apply safe labor practices on the territory of the enterprise and in production premises;

use eco-bioprotective and fire-fighting equipment;

identify and analyze traumatic and harmful factors in the field of professional activity;

types and rules for conducting labor safety briefings;

possible dangerous and harmful factors and means of protection;

the effect of toxic substances on the human body;

measures to prevent fires and explosions;

regulatory documents on labor protection and health, basics of occupational hygiene, sanitation and fire safety;

general safety requirements on the territory of the enterprise and in production premises;

the main causes of fires and explosions;

legal and organizational basis for labor protection at the enterprise, a system of measures for the safe operation of hazardous production facilities and reducing the harmful impact on the environment, preventive measures for safety and industrial sanitation;

rights and obligations of workers in the field of labor protection;

principles of forecasting the development of events and assessing the consequences of man-made emergency situations and natural phenomena;

means and methods for increasing the safety of technical equipment and technological processes

Topic 6 Life safety

organize and carry out measures to protect workers and the population from the negative impacts of emergency situations;

take preventive measures to reduce the level of hazards of various types and their consequences in professional activities and everyday life;

use means of individual and collective protection against weapons of mass destruction; use primary fire extinguishing agents;

navigate the list of military specialties and independently identify among them related professions;

apply professional knowledge during the performance of military service duties in military positions in accordance with the acquired profession;

master methods of conflict-free communication and self-regulation in everyday activities and extreme conditions of military service;

provide first aid to victims;

principles of ensuring the sustainability of economic objects, forecasting the development of events and assessing the consequences of man-made emergency situations and natural phenomena, including in the context of countering terrorism as a serious threat to the national security of Russia;

the main types of potential hazards and their consequences in professional activities and everyday life, principles for reducing the likelihood of their implementation;

fundamentals of military service and state defense;

tasks and main activities of civil defense;

ways to protect the population from weapons of mass destruction; fire safety measures and rules for safe behavior in case of fires;

organization and procedure for conscripting citizens into military service and entering it on a voluntary basis;

the main types of weapons, military equipment and special equipment that are in service (equipment) of military units in which there are military specialties related to the professions of secondary vocational education;

the scope of application of the acquired professional knowledge in the performance of military service duties;

procedure and rules for providing first aid to victims

Topic 7 Techniques for preparing samples for physical and mechanical tests

Preparing samples for testing

have practical experience:

production of prototypes in laboratory conditions;

determining the compliance of the parameters of the tested samples with GOST and TU;

prepare samples from various materials for testing;

prepare documentation for selected samples;

own technical documentation;

make corrections to the geometric dimensions of samples;

carry out degreasing of samples;

draw up a protocol for making changes;

composition, properties, types and purpose of samples to be tested;

procedure for selecting and processing samples;

methods for preparing samples for testing;

state standards and technical specifications for samples of materials and products;

rules for making amendments to the geometric dimensions of samples;

methods for degreasing samples;

locksmith technology;

basic concepts about tolerances and technical measurements;

rules for reading drawings;

methodology for drawing up a protocol for non-compliance of a sample with GOST requirements and making changes

Topic 8 Techniques for preparing laboratory equipment for physical and mechanical tests

Preparing equipment for physical and mechanical tests

As a result of studying the professional module, the student must:

have practical experience:

checking laboratory equipment;

making simple adjustments to laboratory equipment;

performing equipment adjustment work;

monitor the condition of laboratory equipment;

prepare equipment for physical and mechanical tests;

carry out simple adjustments of equipment;

check laboratory equipment;

observe the operation of equipment during testing;

make adjustments when equipment malfunctions are detected;

equipment for conducting physical and mechanical tests, classification, purpose, device, principle of operation;

sequence of preparation and rules for operating equipment for conducting physical and mechanical tests;

possible malfunctions in equipment, ways and means of identifying and eliminating them;

instrumentation used in preparing equipment, their types, purpose, measurement methods

Topic 9 Technology for performing physical and mechanical tests

Performing physical and mechanical tests on laboratory equipment

As a result of studying the professional module, the student must:

have practical experience:

starting and stopping laboratory equipment;

monitoring the operation of equipment during testing;

taking readings from instruments;

performing calculations and graphic work related to the tests;

preparing reports on the work done;

take readings from instruments;

keep work logs;

process and document test and measurement results;

perform computational and graphical work related to the tests;

prepare technical documentation;

purpose and main characteristics of devices;

designation on scales and methods for determining division values;

methods and means of processing, systematizing and recording test and measurement results;

methods and means of performing technical calculations, computational and graphic work;

classification of errors;

errors of indirect measurements and installation;

methods for preventing errors;

current state standards and technical specifications for the documentation being developed, its form, content and execution procedure

Topic 10 Safety rules, industrial sanitation and fire safety

Compliance with safety rules and practices, industrial sanitation and fire safety

As a result of studying the professional module, the student must:

have practical experience:

knowledge of safety techniques when conducting tests;

use of primary fire extinguishing agents;

providing first aid to the victim;

ensure compliance with sanitary and hygienic requirements, norms and rules for labor protection;

handle primary protective equipment and fire extinguishing equipment;

safety and labor protection requirements at the enterprise;

basics of occupational hygiene and industrial sanitation;

norms and rules of electrical safety;

measures, fire extinguishing means;

environmental protection measures

Characteristics of work. Physical and mechanical tests of metals, raw materials, products, alloys, various materials, semi-finished products and finished products for strength, tensile, bending, heat resistance, compression, removal and pushing force, rupture, hardness, air tightness, viscosity, flyiness, twisting, thickness, humidity, water resistance , fat content and other quality indicators on control and testing installations, on Rockwell, Brinell, etc. instruments in accordance with current instructions. Measuring electrical resistance using the bridge method and the ampere-voltmeter method. Determination of density by hydrostatic weighing. Checking the size of the cells and the density of nodes and connections. Determining the percentage of shrinkage and adhesion. Maintaining established test control records. Preparation and degreasing of samples for testing. Selection and preparation of instruments and apparatus for testing. Adjustment of instruments and apparatuses under the guidance of a more highly qualified laboratory assistant. Preparation of developer and fixer according to a given recipe, processing of photographic paper, film and plates, making prints from photographic negatives.

Must know: classification of physical and mechanical tests; basic physical and mechanical properties of the tested metals and materials; basic information about the electrical properties of metals and non-metallic materials; electrical resistivity; methods for determining electrolyte density; methods for preparing samples for testing; basics of electrical engineering within the limits of the work performed; rules for storing and using photographic materials: chemical reagents, photographic paper, photographic plates; methods for preparing developer and fixer according to recipe; the procedure for selecting and processing samples according to the types of properties of the analyzed materials, raw materials, semi-finished products and finished products; the operating principle of the serviced equipment and the rules for handling it during analysis and testing; test results recording system; state standards and technical conditions for testing; purpose of control and measuring instruments, tools and rules for their use.

§ 121. Laboratory assistant for physical and mechanical tests (3rd category)

Characteristics of work. Physical and mechanical tests of raw materials, materials, semi-finished products and finished products with the performance of work on processing and summarizing the results of the tests. Performing calculations to determine the quality indicators of materials, raw materials, semi-finished products and finished products. Determination of compliance of tested samples with state standards and technical specifications. Preparation of prototypes in laboratory conditions. Determination of grinding fineness, uniformity of volume change, setting time and volumetric mass of materials. Calculation of load values based on sample sizes. Determination of temperatures using thermocouples when testing samples for heat resistance. Mounting the thermocouple. Correcting for cold junction temperature. Determination of the normal elastic modulus and shear modulus by radio engineering method, standardization of the installation for determining the moduli. Measurement of magnetic permeability using a ballistic installation. Making corrections for the geometric dimensions of the sample. Regulating the uniformity of sample heating along the length, controlling the heating temperature with thermocouples. Measurement with a thermocouple vacuum gauge of vacuum up to 174 - 1.3 Pa (up to 1.31 - 10 mm Hg). Changing the oil in the forevacuum pump. Checking and adjusting laboratory equipment during testing. Monitoring the passage of an experimental batch of raw materials, materials and semi-finished products in production. Graphic representation of test results.

Must know: arrangement of serviced equipment; recipe, types, purpose and features of materials, raw materials, semi-finished products and finished products to be tested; rules for conducting physical and mechanical tests of varying complexity with performing work on their processing and generalization; the principle of operation of ballistic installations for determining magnetic permeability; main components of vacuum systems, forevacuum and diffusion pumps, thermocouple vacuum gauge; basic methods for determining the physical properties of samples; basic properties of magnetic bodies; thermal expansion of alloys; a method for determining the coefficients of linear expansion of critical points on dilatometers; methods for determining temperature using high- and low-temperature thermometers; elastic properties of metals and alloys; rules for making corrections to the geometric dimensions of the sample; graphing methods; a system of recording tests performed and a methodology for summarizing test results.

§ 122. Laboratory assistant for physical and mechanical tests (4th category)

Characteristics of work. Determination of magnetic susceptibility, magnetic permeability, residual induction, coercive force. Removing the hysteresis loop on the permeameter. Checking the wire for homogeneity and thermoelectromotive force with standards. Temperature control of cold junctions of thermocouples. Recording thermal cycles of cooling and heating of the sample. Creation of high vacuum in installations, measuring it with vacuum gauges. Determination of thermal conductivity, heat capacity and electrical conductivity. Determination of thermal expansion coefficients and critical points using a vacuum dilatometer. Adjustment of used devices and their settings. Determination of the yield strength of a metal using a diagram. Drawing up calculation tables. Calibration of thermocouples and dilatometers for the manufacture and refinement of temperature scales. Measurement of soil temperature with mercury inertial thermometers. Carrying out control tests. Working with light beam oscilloscopes. Select the required vibrator and install it in the magnetic block. Calculation of residual stresses using the ring method based on these measurements. Adjustment of the optical system and oscilloscope timer. Oscillogram processing.

Must know: installation of permeameter, installations for determining the magnetic properties of metals in constant magnetic fields, potentiometers for temperature control, installations for determining thermal conductivity, heat capacity and electrical conductivity, light beam oscilloscopes, ionization and magnetic discharge manometers; ferro-, dia- and paramagnetic materials; dependence of magnetic permeability on field; basic methods for determining magnetic properties; methods of working on a permeameter, ferrotester, installation for determining magnetic susceptibility; fundamentals of materials science; high vacuum measurement methods; methods for determining leaks and eliminating them; thermal properties of metals and alloys; methods for determining thermal conductivity and heat capacity; fundamentals of metallurgy and heat treatment; the magnitude of permissible loads and stresses on the material being tested; strength and yield limits in tension and bending, fatigue limits, maximum stresses.

§ 123. Laboratory assistant for physical and mechanical tests (5th grade)

Characteristics of work. Physical and mechanical tests of all types of welded joints, pipes of various diameters, sheet and profile products with obtaining all characteristics in accordance with technical requirements and conditions. Conducting various non-standard tests. Testing of finished units, products and chains, calibration of special devices adjustable for torque. Assembly of circuits and instruments for non-standard tests. Calibration of registration and recording equipment. Carrying out tests using various strain gauges. Recording decomposition curves and supercooled austenite on an anisometer and temperature curves during the manufacture of control thermocouples. Determination of linear expansion coefficients on automatic high-temperature dilatometers. Determination of the thermal properties of substances using a calorimeter with electronic heating. Determination of the attenuation decrement of samples in the low frequency range. Determination of the purity of metals after zone melting by measuring residual resistance at liquid helium temperature. Filling vessels with compressed and liquefied gases. Carrying out routine repairs and configuration of used equipment.

Must know: methodology for conducting mechanical tests of various welds, pipes, rolled products, finished assemblies and products; principle of calculation and drawing up diagrams for non-standard tests; arrangement of light beam oscilloscopes, strain gauges and strain gauge equipment; arrangement of automatic high-temperature dilatometers, installations for determining internal friction in metals, calorimeters, various types of installations for determining the residual electrical resistance of metals and alloys, anisometers; the basics of dilatometry within the scope of the work performed; iron carbon phase diagram; the influence of alloying elements on the physical properties of metals and alloys; a method for determining thermal expansion on high-temperature dilatometers in an environment of inert gases; rules for drawing isothermal decomposition diagrams of supercooled austenite at low and high temperatures using a bath of liquid nitrogen, oil and liquid tin; properties of materials at low temperatures; properties of liquefied gases; method for determining residual electrical resistance; mathematical processing of experimental data; rules for working with liquid nitrogen; methodology for determining the physical properties of materials.

§ 124. Laboratory assistant for physical and mechanical tests (6th grade)

Characteristics of work. Conducting physical and mechanical tests to determine electrical conductivity and temperature coefficient of resistance in micron-section samples of increased complexity. Removing thermokinematic curves on an anisometer and dilatometer at temperatures from -196 degrees. C and higher. Determination of the thermal properties of substances by electron bombardment. Switching on, servicing and switching off high-temperature heaters. Measurement of electrical conductivity, thermal conductivity, coefficient of thermal expansion, emissivity coefficient at high temperatures in vacuum and inert media. Characterization of thermoelectrode materials at cryogenic temperatures. Determination of the attenuation decrement in the region of high frequencies and high temperatures. Participation in the development of methods for new alloys and metrological certification of installations.

Must know: principles of high-temperature heating; dependence of heating temperature on power consumption; materials for high temperature heaters; the role of heat shields; the principle of heating substances by electron bombardment; the basic laws of electron heating and temperature distribution over a sample when it is bombarded with electrons; methods for determining the physical properties of materials at temperatures above 1000 degrees. C; methods for measuring high temperatures using standard pyrometers; methods for calibrating thermocouples using reference pyrometers; features of the design of high-temperature installations; ways to reduce heat loss; methods for accounting for heat loss and introducing corrections for heat loss through mathematical processing of measurement results.

Secondary specialized education required.