Intelligent control systems in conditions of knowledge uncertainty. “Analysis and optimization of the functioning of multi-level, intelligent and network control systems under conditions of uncertainty

INTRODUCTION

Operating conditions of modern technological complexes lead to the need to take into account in the process of control and management the following types of uncertainty:

1. Low accuracy of operational information received from control objects, arising due to the large error of sensors for measuring technological parameters (flow, pressure, etc.), their low reliability, failures of communication channels, large delays in the transfer of information across control levels, and the inability to measure parameters at all points of the technological process required for the models.

2. Inaccuracy of models of control and management objects, caused by: non-equivalence of solutions to systemic multi-level hierarchical models and individual local problems used in practice; incorrect decomposition of the general control problem, excessive idealization of the technological process model, breaking of essential connections in the technological complex, linearization, discretization, replacement of actual equipment characteristics with passport ones, violation of assumptions made when deriving equations (stationarity, isothermality, homogeneity, etc.).

3. Vagueness in the decision-making process in multi-level hierarchical systems, due to the fact that the presence of clear (precise) goals and coordinating decisions at each level of control and management, and for each local regulatory device, complicates the coordination process and predetermines the long-term iterative nature of the coordination of decisions.

4. Availability of a human operator, including a dispatcher, in the control loop and conducting the coordination process in a real production system in natural language leads to the need to take into account the difficulties of representing the dispatcher’s knowledge in the form of algorithms and the consistency of the computer-generated solution with its assessment.

“The excessive desire for precision has begun to have the effect of nullifying control theory and systems theory, since it leads to the fact that research in this area is concentrated on those and only those problems that can be solved precisely. Many classes of important problems in which the data, objectives, and constraints are too complex or ill-defined to admit of precise mathematical analysis have been and remain aside for the sole reason that they are not amenable to mathematical treatment.”

L.Zade

Among modern production processes there are many that have a set of qualities unexpected for the classical theory of automatic control (TAC). These “inconvenient” or, as they are commonly called, "poorly structured" or "poorly defined" objects have properties such as uniqueness, lack of a formalized purpose of existence and optimality, non-stationary structure and parameters, incompleteness or almost complete absence of a formal description of the object.

Conceptual Framework

management under conditions of uncertainty

Uncertainty factors which are understood as sources of uncertainty, are rather conventionally divided into the following three large groups:

1. uncertainty and incomplete information about the situation, which is used to make decisions on assessing the quality of functioning or forming management of the functioning of the system - uncertainty factor of the system and environment;

2. factors generated by uncertainty, unclear thinking and knowledge of a person- uncertainty that manifests itself during human interaction with the system and its environment;

3. factors due to uncertainty, vagueness(inaccuracy) accumulated knowledge, concentrated in the knowledge bases of artificial intelligent systems, the uncertainty of operating this knowledge in the process of implementation certain logical and logical-algebraic procedures for collecting and processing information, developing, selecting and making management decisions.

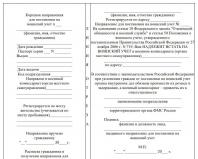

Classification of factors (sources) of uncertainty, requiring their consideration when studying complex systems, is shown in Fig. B.1.

Fig.B.1. Classification of uncertainty factors

Methodology for analyzing and taking into account uncertainty factors in

management in complex organizational and technical systems...

(ACS with DSS and DSS-decision support systems and decision-making systems)

1. Problems and generalized formalization of problems of development and application

making management decisions under conditions of uncertainty….

2. Deterministic game approach to decision making under conditions

in the face of uncertainty…………..……………..……………………..

3. Stochastic approach to solving decision-making problems in

conditions of uncertainty…..………………………………………………………

4. Probabilistic - statistical approach to decision making in

in the face of uncertainty……………………………………………..

5. Probabilistic approach to decision making under conditions of uncertainty

laziness…..…………………………………………………………………………………

6. Fuzzy - stochastic approach to decision making in conditions

uncertainty……………………………..………………………..

7. Possibility theory and the problem of decision making in conditions

uncertainty…………………….…………………………………

8. Fuzzy - possibilistic approach to decision making in conditions

uncertainty……………………………………………………….

9. Linguistic approach to decision making in conditions of uncertainty

fission..………………………..………………………………….

From the point of view of classical TAU, managing semi-structured objects is a rather complex, practically unsolvable problem. This is due to the fact that when constructing a traditional automatic control system (ACS), it is necessary to first formally describe the control object and form control criteria based on a mathematical apparatus that operates with quantitative categories. If it is impossible to give an exact mathematical description of the object and its management criteria in quantitative terms, the traditional TAU turns out to be inapplicable.

For example, classical TAU with deterministic and stochastic systems is successfully used to build automatic control systems for aircraft, power plants, etc., but attempts to extend traditional methods to areas such as biosynthesis, multiphase chemical and technological processes associated with roasting, smelting, catalysis etc., did not give tangible practical results, despite the increasingly complex mathematical methods of their description.

However, in practice, such weakly structured objects are quite successfully managed by a human operator, who benefits from the ability to observe, analyze and remember information, draw certain conclusions, etc., and, as a result, make the right decisions in an environment of incomplete and unclear information. Thanks to his intelligence, a person can operate not only with quantitative(which a machine can do to a certain extent) but also with qualitative non-formalized concepts, as a result of which it quite successfully copes with the uncertainty and complexity of the management process. Therefore, the construction of models of approximate human reasoning and their use in automatic control systems is today one of the most important directions in the development of automatic control systems.

There is no doubt that a significant increase in the efficiency of managing complex objects lies in the creation of intelligent automatic control systems that are capable, to one degree or another, of reproducing certain intellectual human actions related to the acquisition, analysis, classification of knowledge in the subject area of process control, as well as operating knowledge accumulated by a human operator or the system itself during the practical activities of managing an object.

The need to work in these conditions makes it difficult to use standard automation systems and automated process control systems. It is especially difficult to describe the areas of permissible operating modes of equipment in such conditions when setting strict (clear) restrictions for automated process control systems and automation systems lead to automatic or manual shutdown of these systems. Therefore, it seems extremely important to be able to use it to describe and formalize the areas of permissible operating modes of equipment. theories of artificial intelligence (AI) and intelligent systems (IS).

Due to the rapid development of computer technology recently the use of new methods of intelligent control in industry began. And although the first applications of intelligent self-propelled guns took place in Europe, such systems are being implemented most intensively in Japan. Their range of applications is wide: from controlling industrial robots, distillation units and blast furnaces to washing machines, vacuum cleaners and microwave ovens. At the same time, intelligent self-propelled guns make it possible to improve product quality while reducing resource and energy costs and provide higher resistance to the influence of disturbing factors compared to traditional self-propelled guns.

An intelligent system means(K.A. Pupkov) a set of technical means and software united by an information process, working in conjunction with a person (a team of people) or autonomously, capable of synthesizing a goal based on information and knowledge in the presence of motivation, making a decision to act and finding rational ways to achieve goals.

The main architectural feature that distinguishes intelligent control systems (IMS) from "traditional" is a mechanism for obtaining, storing and processing knowledge to implement its functions.

The creation of intelligent control systems is based on two principles: situational control (control based on the analysis of external situations or events) and the use of modern information technologies for knowledge processing (expert systems, artificial neural networks, fuzzy logic, genetic algorithms and a number of others).

One way out of this situation is to use intelligent control methods that involve abandoning:

- - the need to obtain an accurate mathematical model of the object;

- - orientation towards the use of “hard” (usually linear) algorithms for the formation of control actions;

- - the desire to use, at all costs, synthesis techniques known to the developer, which have previously proven themselves positive for other, simpler classes of objects.

Before moving on to intelligent control, one cannot help but note the world-recognized and classic machine control trends developed by domestic scientific schools. These are the works of Balakshin B.S., Bazrov B.M., Bzhozovsky B.M., Gornev V.F., Morozov V.P., Kolosov V.G., Ratmirov V.A., Solomentsev Yu.M., Pusha V.E., Sosonkina V.L., Timiryazev V.A., Zakovorotny V.L., Tugengold A.K. and etc. . In particular, the works are devoted to the creation of adaptive control systems for machine tools based on quality indicators of product manufacturing. Flexible automated production (FAP), which makes it possible to reduce costs, increase reliability and flexibility (ability to re-adjust) functioning with frequent changes of control programs, are described in detail in the works. The creation of CNC programs and the features of their implementation as part of integrated automated production are discussed in.

A detailed analysis of modern methods of controlling technological processes and equipment is given in the work, which shows the achievements of modern control theory, in particular, the use of methods of analytical design of regulators (Letov A.M. et al.), modal control (Pospelov G.S. et al. ), inverse problems of dynamics (Krutko P.D. and others), invariant control (Shchipanov G.V., Kulebakin V.S., Petrov B.N. and others), adaptive control (Tsipkin Ya.D. and etc.), etc. It is noted that the pinnacle of ideas in the synthesis of control systems is the analytical design of regulators. A fundamentally different way of constructing control systems, based on the synergetic theory of control, is described in. The principles of evolutionary transformations and self-organization, based on a synergetic approach, in a control system, the state coordinates of which interact with the environment, are set out in the works. All of these approaches and principles for the synthesis of control systems have their advantages and disadvantages, but what they all have in common is that they are based on a mathematical model of the control object obtained in one way or another, and the mathematical model is a system of differential or difference equations that describe the physical the essence of processes or objects. A fundamentally different approach to control is to use mathematical models of knowledge about the controlled object, i.e. use of intelligent control methods. In relation to TO, this area of research is presented in the works.

The basis of intelligent control is the idea of building highly organized automatic control systems, based on the use of models of variable complexity and uncertainty, with the implementation of such inherent human intellectual functions as decision-making, behavior planning, training and self-learning in a changing external environment. By learning we need to understand the ability of a system to improve its behavior in the future (in relation to TO - to improve the quality of processing), based on the experimental information that it received in the past, about the results of interaction with influencing factors. Self-learning is learning without external adjustment, i.e. without instructions from the “teacher”-operator.

An intelligent control system (ICS) is considered to be one in which knowledge about the unknown characteristics of the control object and the environment is formed in the process of learning and adaptation, and the information obtained is used in the process of automatic decision-making so that the quality of control improves.

A necessary feature of an IMS is the presence of a knowledge base containing information (facts), models and rules that make it possible to clarify the assigned management problem and choose a rational way to solve it. Intelligent systems are often spoken of as knowledge-based systems. Depending on the nature of the intellectual functions being implemented, i.e. on the level of intelligence, a distinction is made between IMS, intellectual “in the big” and “in the small”.

According to control systems, intelligent “in the big” are systems organized and functioning in accordance with the following five principles (in their entirety).

- 1. Interaction with the real outside world using information communication channels.

- 2. Fundamental openness of the system in order to increase intelligence and improve one’s own behavior.

- 3. The presence of mechanisms for forecasting changes in the external world and the system’s own behavior in a dynamically changing external world.

- 4. The presence of a multi-level hierarchical structure, built in accordance with the rule: increasing intelligence and decreasing requirements for the accuracy of models as the level of hierarchy in the system increases (and vice versa).

- 5. Maintainability of functioning (possibly with some loss of quality or efficiency, i.e. with some acceptable degradation) in the event of a break in connections or loss of control actions from higher levels of the hierarchy of the control structure.

Control systems that are intelligent “in small ways” do not satisfy the principles listed above, but use knowledge during operation (for example, in the form of rules) as a means of overcoming the uncertainty of input information, inaccuracy in the description of the controlled object or its behavior.

Based on all of the above, we can draw the following conclusion. Given the multiplicity of factors influencing the achievement of processing quality on metal-cutting machines, the “fuzzy” information about these factors, the stochasticity of the cutting process itself, as well as the variety of methods for ensuring a given processing accuracy, intelligent control systems are a promising area of research and development in machine tool equipment.

Nowadays, the most widely used methods of intelligent control belong to the following four classes:

- - expert systems (ES);

- - fuzzy controllers (NR);

- - neural networks (NN);

- - genetic algorithms (GA).

Expert systems deal with artificial intelligence tasks at the top level, working with symbolic information to draw conclusions about the environment and formulate management decisions taking into account the nature of the current (or predicted) situation. Expert systems accumulate heuristic knowledge and manipulate it, trying to imitate the behavior of an expert.

Figure 1.2 shows an example of constructing an expert regulator, which is a combination of an ES and a traditional regulator (or system of regulators) in relation to maintenance management. The technological system proposed in the model has a more complex structure (with detailed detailing of individual ES blocks), which are based on the principle of decision-making to make predictive corrections in the process of manufacturing parts, taking into account the specific situation. The expert system, as in Figure 1.2, forms the upper, supervisory level of management and includes a number of subsystems.

Identification and forecast subsystem - ensures that a mathematical model of a control object is found directly in the process of operation, based on the results of observations of its input/output variables. That is, the tasks of the block include collecting the information necessary for decision-making. This block carries out software adjustment of the movements of the working bodies, measures and identifies the parameters of the state of the external environment - F, control actions - U, the results of the AIDS system - Y.

The database contains continuously updated data (previous, current, forecast) about the characteristics of the AIDS system and the external environment, as well as information about the boundary (critical, maximum permissible) values of the corresponding parameters. The knowledge base contains knowledge about the specifics of the operation of a particular TO, goals, strategy and control algorithms, the results of identification and forecast of the characteristics of the AIDS system.

The logical inference subsystem selects the rational (most suitable at the time of processing of a certain part at a maintenance facility) structure and parameters of the controller, as well as, possibly, identification and prediction algorithms.

The interface subsystem is designed to organize an interactive mode for filling the knowledge base with the participation of an expert (training mode) and ensuring communication with the user-operator (professional worker), including an explanation of the mechanism for making certain management decisions (operating mode).

The difference between the expert system architecture shown in Figure 1.2 and the architecture of conventional (static) expert systems is that it provides the following important functions:

- * construction of a dynamic model of an object and its environment;

- * maintaining contact with the outside world (sensors, DBMS, regulators, other ES).

This circumstance allows us to classify the expert system in question as a class of dynamic (“active”) expert systems, or real-time expert systems that can make up for the lost contribution of a professional worker with his experience, knowledge and skills in achieving quality processing.

Fuzzy controllers. The ideas of fuzzy logic, first expressed in 1964 by the American L. Zadeh, a well-known specialist in the field of systems theory, found their first application in problems of controlling real technical objects in Europe. In 1974, the works of English scientists E.H. were published. Mamdani and S. Assilian, devoted to the problem of regulating a steam generator plant using specially designed fuzzy rules (products).

The typical structure of an IMS with HP is shown in Figure 1.3. For simplicity, we will assume that the control object (for example, a feed drive based on a direct current motor (DC)) is one-dimensional, i.e., it has one input (control signal - u) and one output (rotation speed of the motor shaft - y). The control error e, which is the difference between the reference influence and the output of the object (controlled variable) y, is fed to one of the inputs of the fuzzification block. The other input of this block receives a derivative signal calculated using a differentiating device (DE).

The purpose of the fuzzification block is to transform the values of error signals e and its derivative into linguistic variables defined by membership functions. Here A i and B j are, respectively, the values (terms) taken by the linguistic variables “Control error” and “Error derivative”. An example of constructing membership functions is shown in Figure 1.3, where the following notation is used:

Z - “Close to zero” (zego);

MR - “Average positive” (middlepositive);

LP - “Large positive” (large positive);

MN - “Middle negative” (middlenegative);

LN - “Large negative” (largenegative).

The knowledge base stores knowledge in the form of rules, the left parts of which contain conditions regarding the above values of the linguistic variables “Control error” and “Error derivative”, and the right parts contain statements regarding the values of the linguistic variable “Increment of control action” (index k here means k -th moment of time t k). These rules can take the following form:

- 1) IF (Control error = Close to zero) AND (Error derivative = Close to zero), THEN (Control action increment = Close to zero);

- 2) IF (Control error = Average positive) AND (Derivative error = Large negative), THEN (Increment of control action = Average positive), etc.

It is assumed that the implementation of these rules guarantees the fulfillment of certain requirements for the system related to ensuring the desired type of its transient function (given speed, monotony, weak oscillation of the transient process, for example, according to control and disturbing influences for the servo drive of a metal-cutting machine). A possible option for specifying membership functions that determine the basic values of the linguistic variable “Increment of control action” in the form of single-point fuzzy sets (singletons) is shown in Figure 1.4.

The operation of the logical inference mechanism is based on the “maximum-minimum” method or the “maximum-product” method. The use of these methods makes it possible to obtain the resulting membership function of the linguistic variable “Increment of control action” (Figure 1.4) taking into account specific (i.e., measured at the moment t k) values of the signals e k and - inputs of the fuzzy controller.

And finally, the transition from the resulting fuzzy set, described by the membership function, to a single (clear) value of the output variable is carried out in the defuzzification block using the center of gravity method.

For the case considered in Figure 1.4, this value is calculated as

where are the values of the membership function at points -c 1, -c 2, 0, -c 1, -c 2, called activity levels of the corresponding rules and calculated using the inference mechanism.

The output of the fuzzy controller u k is found by the formula

where u k-1 is the previous value of the control action u; - increment calculated at the kth clock cycle of the controller.

Another type of fuzzy controller is a Sugeno type controller. In this case, only the left parts of the rules (conditions) contain linguistic variables; the right parts of these rules (outputs) are linear combinations of the controller input variables plus a constant component (bias). For example, fuzzy rules may look like this:

1) IF (Control error = Close to zero) AND (Error derivative = Close to zero), THEN

2) IF (Control error = Average positive) AND (Derivative error = Large negative), THEN

Here are the specified (selected by the expert) numerical coefficients; - the values of the error signal and its derivative measured in the kth cycle. The resulting output is a weighted average of the outputs of each rule (1.3)

where is the activity level of the i-th rule; N is the number of such rules; - increment calculated using the i-th rule for specific values.

The main advantage of using fuzzy controllers in maintenance management is the ability to effectively control complex dynamic objects that are part of the AIDS system under conditions of uncertainty of their characteristics by modeling the knowledge processing mechanism by analogy with the behavior of a highly skilled worker (operator).

Neural networks. The history of artificial neural networks begins with the work of American scientists W. McCulloch, W. Pitts (1943 - a model of a formal neuron) and F. Rosenblatt (1958 - a single-layer neural network, which he called a perceptron). Today, neural networks (NNs) refer to parallel computing structures that model biological processes typically associated with those of the human brain. NNs have the ability to acquire domain knowledge by learning from examples and adjusting their weights to interpret the high-dimensional data presented to them.

Figure 1.5 shows a block diagram of a direct propagation NS - a multilayer perceptron. Circles (vertices) indicate elementary information converters - neurons, and arrows (arcs) - connections between them that have different “strengths” (weights of synaptic connections). As can be seen from Figure 1.5, the perceptron in question consists of several layers of neurons:

- * input layer to which a set of input signals is supplied;

- * one or more “hidden” (intermediate) layers;

- * output layer of neurons.

The essence of the NN training process is to perform the following multi-step procedure.

Step 1. Specify a training set (“problem book”)

the elements of which are training pairs. In this case, the 1st input vector (or 1st input image) presented to the neural network; - vector of reference (required) NS reactions in response to the 1st input vector; L is the number of different training pairs.

Step 2. The initial state of the neural network is established by assigning some random (small) values to all its weights. - the weight of the connection connecting the output of the i-th neuron of the k-th layer with the input of the j-th neuron of the (k + 1)th layer.

Step 3. An input vector is supplied to the network input; the reactions of neurons in the output layer are determined.

Step 4. The difference between the desired network response and its actual output is calculated, i.e., as well as the total square error

Step 5. The weights of the neural network are adjusted in such a way as to reduce the error.

Step 6. Steps 3-5 are repeated for each pair of the training set until the error on the entire set reaches a small, predetermined value E*.

The result of training is such an adjustment of the weights of synaptic connections in which the network associates each input vector with the required (or close to it) output.

One of the first algorithms that successfully proved itself in training multilayer neural networks was the backpropagation algorithm (Back-ProgationAlgorithm) proposed in 1986 by Rummelhart (USA) and his colleagues, which subsequently underwent numerous changes and improvements.

Today, more than 200 varieties of NS are known. In addition to the multilayer perceptrons mentioned above, these are:

- * dynamic (recurrent) NS;

- * networks based on radial basis functions;

- * Hopfield networks;

- * Kohonen networks;

- * neocognitrons, etc.

Figure 1.6 shows an example of using a NN to solve the problem of controlling a complex dynamic object (as in the example with a fuzzy controller, maintaining a given speed for a DC motor drive is considered). In this case, the NS acts as a nonlinear regulator, which, after completing the learning process, ensures a minimum mismatch between the outputs of the reference model (EM) and the automated control system as a whole.

The advantages of using multilayer NS as TO controllers are explained by a set of their properties: 1) signals in such NS, as in automatic control systems, propagate in one, forward direction; 2) the universal approximation properties of these networks play a key role in the formation of the necessary nonlinear control algorithms; 3) the ability of a multilayer neural network to learn gives adaptive properties; 4) the ability of a neural network to parallel process both analog and discrete signals makes it natural to use them to control multidimensional objects. The implementation of neurocontrollers based on trained neural networks does not pose any fundamental difficulties: existing microprocessor tools can fully implement the functions of the neural network. The inclusion of a multilayer NS in the control loop expands the phase space of the object and increases the number of its degrees of freedom, thereby making it possible to synthesize optimal control laws.

Genetic algorithms (geneticalgorithms). This is a large group of adaptive search and multiparameter optimization methods that have been intensively developed in recent years, both for their independent use and in combination with other intelligent control methods.

The very name of these algorithms indicates that their origin is associated with the use of the principles of natural selection and genetics. Traditional search methods usually assume that the target function under study is differentiable with respect to parameters and, as a rule, use gradient procedures. Genetic algorithms (GAs) differ from conventional optimization methods in a number of circumstances. At its core, GAs are a method of parallel search for a global extremum, based on the use in the search process of several appropriately coded points (candidate solutions), which form a population developing according to certain random laws. The selection mechanisms used in this case, first clearly formulated by Charles Darwin (“Survival of the fittest!”), make it possible to weed out the least suitable options and, conversely, highlight and then enhance the positive qualities of those options that most fully meet the goal.

Let us outline the range of problems solved with the help of GA in relation to TO.

Optimization problems occupy one of the central places in the design of various classes of self-propelled guns. The reason for this is the natural desire to choose the simplest option for constructing a system or model while meeting the specified requirements for the quality of its functioning (structural synthesis problem) or to find optimal settings for the parameters of a multicomponent system given its structure (parametric synthesis problem). Several examples of formulations of corresponding problems are given.

Task 1. It is required to find the optimal algorithm for identifying and predicting the characteristics of an object, used as part of an industrial control system with an expert controller (see Figure 1.2). Variable parameters are the numerical coefficients of the regression model, the number of basis functions or the order of the regression equations. The objective function is the identification and forecast error, estimated as the difference between the outputs of the control object and its model at the current (or future) point in time.

Task 2. It is required to select the form and relative arrangement of the membership functions of a fuzzy controller that ensures the specified quality of control processes in the automatic control system. Variable parameters - numerical coefficients a i,b j,c s of membership functions (see Figure 1.5); number of membership functions. The target function is a quality indicator (functional), the minimum of which corresponds to the reference transient processes.

Task 3. It is required to select the structure (topology, architecture) of a multilayer perceptron used as a nonlinear controller in a technical control system, shown in Figure 1.6. Variable parameters are the number of layers and the number of neurons in each layer of the neural network. The objective function is the network training error, which is the mismatch between the outputs of the object and the reference model of the system.

In all the examples given, the optimization problem takes the following mathematical formulation: find such values of variable parameters V 1, V 2, ..., V n that provide a minimum of the objective function f(V 1, V 2, ..., V n) provided that the specified parameters V 1, V 2, ..., V n satisfy a certain admissible region. Setting the area of restrictions in each specific case is dictated by the specifics of the problem being solved. For example, in Problem 2, the type of area is determined by the choice of the boundaries of the intervals within which the required optimal parameters of the membership functions are sought. In task 3, the corresponding restrictions are related to limiting the maximum permissible complexity of the class of NN under study, etc.

When using traditional multiparameter search algorithms to solve the above problems, a number of difficulties arise, which include:

- * a sharp increase in computational costs and search time with an increase in the number of varied parameters (“the curse of dimensionality”);

- * local nature of search algorithms, associated with the need to calculate derivatives (gradient) of the target function at each search step;

- * the possibility of the search algorithm “freezing” in the vicinity of one of the local extrema;

- * low noise immunity of the algorithm;

- * low search efficiency in the presence of “gully” situations.

The attractiveness of GAs lies precisely in the fact that they are largely free of these disadvantages.

According to the terminology of GAs, borrowed from genetics and the theory of evolution of living nature, they deal with a population of “individuals,” each of whom is a candidate for solving the problem under consideration. Each individual is assigned a certain “fitness index” depending on how successful a given particular option for solving a problem is. For example, one of the objective functions mentioned above (see tasks 1-3) can act as such a suitability index. Next, the most fit individuals are given the opportunity to “reproduce” by “crossing” with other individuals in the population. As a result of this, new individuals appear - “descendants”, who inherit part of the characteristics from each of their “parents”. The least fit members of the population, as a result, “die out.” The resulting new population of possible solutions forms a new “generation” that retains in a much greater proportion those qualities (characteristics) that were inherent in the best representatives of the previous generation. By applying the above scheme from generation to generation, and by encouraging crossbreeding and the exchange of traits among the fittest individuals first, the population can be progressively improved by preserving and enhancing the strengths of the individuals. In other words, the search process will explore the most promising, promising areas of the variable parameter space. When the GA functions correctly, the population converges to the optimal solution to the problem.

It is generally accepted that genetic algorithms do not guarantee finding a global optimum, but their strength lies in the fact that they allow “quickly enough” to find “good enough” solutions to a wide range of problems, including those that are difficult to solve by other methods.

The history of the use of genetic algorithms begins with the works of R. Holstien and De Jongh, in which the capabilities of GAs for solving multiparameter optimization problems were first demonstrated using a number of examples. In 1975, J. Holland’s monograph “Adaptation in Natural and Artificial Systems” was published, which provided a theoretical justification for the method and formulated the basic principles underlying it. And finally, D. Goldberg’s book “Genetic Algorithms in Search, Optimization and Machine Learning Problems,” published in 1989 and becoming a classic, gained great popularity, containing a large number of examples and possible formulations of problems from various application areas solved using GAs.

In recent years, the scope of application of GA has expanded significantly. These methods have been shown to be effective in solving problems such as:

- * identification of complex dynamic objects;

- * selection of the optimal configuration of multi-agent robotic systems;

- * synthesis of optimal control algorithms for multi-link robotic manipulators;

- * optimal control of spacecraft docking;

- * planning vehicle routes under obstacles;

- * structural synthesis of design solutions, synthesis of schedules

and many others.

The use of GA covers not only the class of traditional optimization problems, but also quickly extends to control problems of complex dynamic objects under conditions of uncertainty. Therefore, in problems of controlling machine tools, GAs can also be used to solve a wide range of problems.

To ensure the specified quality of processing at a maintenance facility, it is necessary to organize intelligent management at all levels of the automated control system: organizational, coordination and tactical. This means that both the system of regulators and the identification and forecasting unit as part of the ES must have “intellectual abilities”. Fuzzy, NN controllers and their varieties are often used as regulators of nonlinear control objects, and for identification and forecasting systems - neuro-fuzzy systems (ANFIS - AdaptiveNeuro-FuzzyInferenceSystem) and various types of neural networks. The ES themselves can also be built based on the use of “crisp” or “fuzzy” logic. Thus, an ES can be developed on the basis of a NN or fuzzy rules, or both at the same time. Therefore, when organizing intelligent maintenance management, it is more expedient to create neuro-fuzzy (hybrid) ES that have broad capabilities to use the advantages of both fuzzy logic and neural networks. Moreover, it is necessary to use a mixed (hybrid) management strategy at all levels of the TOMS, because this will make it possible to most fully use the advantages of intelligent management methods not only at the upper level of management (organizational and coordination), but also at the lower (tactical) level, where there is the need for nonlinear algorithms for various strategies for controlling actuators in real time.

Concepts: intelligent system (IntS), intelligent control system (IntSU)

The concept of “intelligent system” is interpreted differently by different researchers. Let's consider the main ones, including accompanying explanations.

Intelligent system is an information and computing system with intelligent support for solving problems without the participation of an operator (decision maker - decision maker). Intelligent system is an information and computing system with intelligent support for solving problems with the participation of an operator - decision maker. Basic intelligent technologies, including artificial neural networks (ANN), genetic algorithms, fuzzy logic, can be effectively used in the creation of control systems. At the same time, the feasibility of their use is determined by the ability to implement distributed calculation schemes, which makes it possible to expand the search space without significantly increasing the complexity of the necessary calculations; the ability to describe control processes using “simple” language, close to natural; the possibility of non-analytical representation of nonlinear control objects and description of processes characterized by ambiguity and a large number of special situations; the ability to quickly search in the space for solutions to poorly formalized problems.

Intelligent systems These are knowledge-based systems. When processed on a computer, knowledge is transformed similarly to data: 1) Knowledge in human memory as a result of thinking. 2) Material carriers of knowledge (textbooks, teaching aids). 3) Field of knowledge - a conditional description of the main objects of the subject area, their attributes and patterns connecting them. 4) Representation of knowledge based on any model (production, semantic, frame or other). The production model or rule-based model allows knowledge to be represented in the form of sentences like "If , That" A semantic network is a directed graph whose vertices are concepts and whose arcs are relationships between them. A frame is a data structure for representing some conceptual object. 5) Knowledge base on computer storage media. When using the production model, the knowledge base consists of a set of rules. The program that controls the enumeration of rules is called an inference engine (reasoning engine, inference engine, deductive engine, interpreter, rule interpreter, solver). The output machine works cyclically. In each cycle, it looks at existing facts from the working memory (database) and rules from the knowledge base, and then compares them. The set of selected rules constitutes the so-called conflict set (that is, in a specific situation several rules can be applied at once). To resolve a conflict, the inference engine has a criterion by which it selects a single rule, after which it is triggered. This is expressed in the entry of facts (recommended actions) that form the conclusion of the rule into working memory or in changing the criterion for selecting conflicting rules. If the conclusion of the rule includes the name of an action, then it is triggered. The inference engine is based on the principle of modus ponens, which is interpreted as follows: “If statement A is known to be true and there is a rule of the form “if A then B,” then statement B is true.”

Under intelligent systems understand any biological, artificial, or formal system that exhibits the ability to engage in goal-directed behavior. The latter includes the properties (manifestations) of communication, knowledge accumulation, decision making, learning, adaptation. Artificial intelligence research is based on a knowledge approach. Reliance on knowledge is the basic paradigm of artificial intelligence. In the work, interpretations of knowledge are combined into four groups (or levels): psychological, intellectual, formal-logical and information-technological. Psychological interpretation of knowledge - mental images, mental models. Intellectual interpretation of knowledge is a set of information about a certain subject area, including facts about objects of a given subject area, the properties of these objects and the relationships connecting them, descriptions of processes occurring in a given subject area, as well as information about ways to solve typical problems. Formal-logical interpretation is formalized information about a certain subject area, used to obtain (infer) new knowledge about this subject area using specialized procedures. Information technology interpretation - structural information stored in computer memory and used in the operation of intelligent programs.

In the works of D.A. Pospelov and his colleagues described the following conceptual properties of knowledge: internal interpretability, understood as the presence of unique names identifying each information unit; structure, which determines the possibility of recursive nesting of individual information units into each other; external connectivity, defining the possibility of establishing functional, casual and other types of relationships between information units; scalability, characterizing the possibility of introducing various metrics to record quantitative, ordinal and other relationships of information units; activity, reflecting the ability to initiate certain appropriate actions when new information appears.

Intelligent information system(or knowledge-based system) is based on the concept of using a knowledge base to generate options for solving applied problems of various classes, depending on the specific information needs of users. The main purpose of building such systems is to identify, study and apply the knowledge of highly qualified experts to solve complex problems that arise in practice. When building knowledge-based systems, knowledge accumulated by experts in the form of specific rules for solving certain problems is used. This direction aims to imitate the human art of analyzing unstructured and semi-structured problems.

In the applied theory of intelligent systems (IntS), the control system is considered only in close interaction with the external world surrounding it, and the intelligent system is interpreted as a set of active subjects and objects (subjects) opposing them, generated either by the situational possibility of the active existence of the subject, or by the target task of some systemic or an extra-systemic subject, and all the elements of any nature that make up the intellectual system are under the influence of the external world common to them.

In the work of A.V. Timofeev and R.M. Yusupov said that IntSU includes elements of artificial intelligence that allow one to form concepts and accumulate knowledge, plan behavior and make decisions in uncertain conditions, recognize images and form a model of the environment. Introduction of intelligence elements into automatic control systems (ACS) significantly expands their functionality compared to adaptive self-propelled guns. As a result of intellectualization, self-propelled guns acquire the ability to solve certain types of intellectual tasks that were usually assigned to humans. Therefore, IntSU are increasingly used in cases where the situation does not allow (does not justify) the direct participation of a human operator in the control process or when it is necessary to reduce the operator’s labor intensity when the control object is operating in normal modes.

The need for intellectualization of automatic control systems usually arises in cases where control objects are complex (for example, objects with nonlinear dynamics operating under conditions of uncertainty), and their description and interaction with the environment is difficult to structurize and formalize. The incompleteness of the description is manifested both in the a priori uncertainty of the model of the object and the environment, and in the uncertainty and diversity of management goals. Often the description of the behavior of such objects is vague and contains qualitative information (expert assessments, plausible conclusions, membership functions). Solving control problems in such conditions is impossible without the use of artificial intelligence methods, that is, without the intellectualization of self-propelled control systems.

Thus, the intellectualization of automatic control systems comes down to the representation and processing of knowledge about the environment, object and control system using the necessary means of learning and adaptation. This knowledge and tools make it possible to refine the model of the control object and the environment and give the ACS fundamentally new properties, similar to the intellectual abilities of a human operator or expert. The characteristic features of IntSU are their ability to learn and self-learn through the formation of knowledge, to synthesize and identify patterns of behavior, to recognize and analyze situations, self-organization and adaptation in relation to various factors. These abilities make it possible to compensate for various factors of internal and external uncertainty that arise during the operation of the ACS, and thereby improve or optimize the quality of control.

Following , IntSU we will call such a system in which knowledge about the unknown characteristics of the control object and the environment is formed in the process of learning and adaptation, and the information obtained is used in the process of automatically making control decisions so that the quality of control improves. Note that the processes of learning and adaptation can occur either in isolation from the control process (for example, in the training mode with a teacher, usually played by a human operator or expert), or directly in the process of automatic control in real time.

Let us consider the features of the functional structure of typical representatives of the class of intelligent control systems, interpreting them in relation to technological control objects (units, machines, machine complexes).

This article is also available:

Rosenberg Igor Naumovich

Intelligent control// Modern control technologies. ISSN 2226-9339

. — . Article number: 7608. Publication date: 2017-04-10. Access mode: https://site/article/7608/Introduction

Intelligent management is a generalization of semiotic, cognitive and information management. In intelligent transport management, the following areas are distinguished: intelligent transport systems, intelligent semiotic control and intelligent cognitive control. Intelligent semiotic control is associated with different forms of logic, a system of products, and evolutionary algorithms. Intelligent cognitive control is considered as a synthesis of human computer control using associative channels and analysis of tacit knowledge. Intelligent control is considered as a means of making decisions under conditions of uncertainty. Intelligent information management is considered as supporting intelligent management through information technology.

The need for intelligent control

As society developed and objects and management tasks became more complex, management technologies also changed. The problem of “big data” has become most acute in managing complex situations. It creates an information barrier for “organizational management” technologies. Modern management is characterized by the growth of poorly structured information. This causes a transition to intelligent management, which, in turn, leads to the need to use knowledge management technologies. The basis of intelligent management is intelligent systems and intelligent technologies. An intelligent system is a technical or software-hardware system capable of obtaining creative solutions to problems belonging to a specific subject area, knowledge about which is stored in the memory of such a system. In a simplified way, the structure of an intelligent system includes three main blocks - a knowledge base, a solver and an intelligent interface. The solver is the dominant component of the intelligent system. In first-order logic, a solver is a mechanism for obtaining solutions to logical expressions. In multi-agent systems, which are classified as artificial intelligence, the concept of a solver is also used. An agent is a problem solver, which is a software entity capable of acting in the interests of achieving set goals. In symbolic modeling, the s-solver is the message specialization value. Efimov E.I. was one of the first in Russia to introduce this concept. . This short list shows the importance of the solver for intelligent systems and intelligent technologies.

Intelligent control within the framework of applied semiotics

Semiotics studies the nature, types and functions of signs, sign systems and human sign activity, the sign essence of natural and artificial languages with the aim of constructing a general theory of signs. In the field of semiotics, there is the direction of “applied semiotics”, the founder of which is D.A. Pospelov.

In semiotics, there are two areas of application of signs: cognition and communication. This divides semiotics into two parts: semiotics of knowledge; semiotics of semantic communications. The basis of intelligent control is the semiotic system. According to Pospelov, the semiotic system W is an ordered eight of sets:

W=< T, R, A, P, τ, ρ, α, π>, (1)

Where

T - set of basic symbols;

R - set of syntactic rules;

A - a lot of knowledge about the subject area;

P is the set of rules for deriving solutions (pragmatic rules);

τ—rules for changing the set T;

ρ—rules for changing the set R;

α are the rules for changing the set A;

π — rules for changing the set P.

The first two sets generate the language of the system W, and τ And ρ carry out its change. Rules α change a lot of knowledge about the subject area. If we consider knowledge as axioms of a formal system (which is formed by the first four elements of W), then the rules α , essentially change the interpretation of the basic symbols and, therefore, the correctly constructed formulas of the language of the semiotic system W.

The first four sets form a formal system FS, elements from five to eight form the rules for changing the formal system. By doing this, they ensure the adaptation of the formal system, “adjusting” it to solve tasks and problems that, within the framework of the system, FS can't be solved.

Thus, the semiotic system (1) can be defined as a composite dynamic system: W=

Therefore, the semiotic system can be given a new interpretation. Composite dynamic system: W=

Rules MFsi = (τ, ρ, α, π), those changing the state of the formal system (control object) are connected by a dependence that exists in the elements of the semiotic triangle (Frege's triangle). This means that applying one of the four rules causes the remaining rules to be applied.

These dependencies are complex, their analytical representation is missing, and this is difficult and is the subject of research into semiotic systems of artificial intelligence. Therefore, it is simpler to use the information approach and information modeling.

Extensions of formal control systems in the form of dynamic components MFsi provide the properties of openness of systems. They create the opportunity to adapt the control object to management influences and changing external conditions.

This, in particular, allows us to significantly expand the possibilities of supporting decision-making in conditions of uncertainty, incompleteness and inconsistency of initial information.

Types of uncertainties when implementing intelligent control

Traditional control methods, including some types of intelligent control, are based on the assumption that state and control models of an object accurately describe its behavior. Methods based on this assumption are included in classical control theory. However, in conditions of increasing volumes, growth of unstructured information and the influence of the external environment, deviations from this condition are characteristic.

Almost any model is a simplified description of a real object, its state and its behavior. The degree of simplification may be acceptable or create uncertainty. In the dynamics of the behavior of a control object, some characteristics of the object can change significantly during its operation. All this creates uncertainties in various models for describing an object and makes it difficult to control it, including intellectual control. The typical control model underlying the control algorithm or the set of established control rules is called nominal.

Under conditions of significant uncertainty, classical methods of control theory are inapplicable or produce unsatisfactory results. In these cases, it is necessary to use special methods of analysis and synthesis of control systems for objects with uncertain models. The first step is to assess the type and value of uncertainty.

There are main types of uncertainties in management models: parametric, functional, structural and signaling.

Parametric uncertainty means that the constant parameters of the model are unknown or imprecisely determined. For example, instead of point values, there are interval values. When moving to information-measuring systems, we can talk about the lack of information certainty of parameters. Therefore, in many cases, the actual values of the parameters may differ significantly from the accepted nominal ones.

Signal uncertainty means that management action or information flows in the control system are affected by interference that significantly changes the nominal signals. Such signals that deviate the control process from the nominal one are called disturbances or interference. The difference is that the interference is passive and only changes the signal-to-noise ratio. The disturbance changes the signal with the same interference.

Modern intelligent control systems must ensure the autonomous operation of many related technical objects. This gives grounds to talk about an intelligent control system (ICS). An intelligent system must solve complex problems, including planning, goal setting, forecasting, etc. For the versatility, adaptation and accuracy of solutions, it is advisable to use multi-purpose intelligent control.

The multi-level architecture of the intelligent control system consists of three levels: conceptual, information and operational (Fig. 1). A system built using this architecture controls the behavior of complex technical objects in conditions of autonomous and collective interaction. The conceptual level is responsible for the implementation of higher intellectual functions

Fig.1. Multi-level intelligent control.

At the conceptual level, a semiotic (sign) representation of knowledge is used and messages are exchanged with other levels. The information and operational levels contain modules that support various intellectual and information procedures and transform them into management.

The main task of management at the conceptual level is the storage, acquisition and use of conceptual knowledge presented in semiotic (symbolic) form.

Composite dynamic system: W=

The acquisition of knowledge is based on a model of the real situation in the external environment. The highest intellectual functions include the functions of setting the main goal and subgoals, planning behavior and distributing influences in the general plan of action.

At the information management level, information modeling problems are solved, the main of which are: construction of an information situation, information position, which correspond to the component FSi. At the information management level, the tasks of constructing an information structure are solved, which is a reflection of the system of rules at the conceptual level and corresponds to the component Mfsi. The linguistic environment of semiotic control at the information level is realized by the use of various information units. Which serve as the basis for constructing an information situation, information position and information design.

At the operational (executive) level, management decisions (managerial influences) are implemented. Managerial influences necessarily change the information position of the control object. Management influences can change, if necessary, the information situation of the control object. At the same time, there is most often no need to change the information situation. The main task of this level is to change the state and position of the control object and report changes to the conceptual level.

Multi-level architecture has a number of features. It includes a number of human cognitive functions. It is based on the use of an information approach to intelligent management.

It is worth noting the difference between intellectual and information technologies. Information technologies perform the functions of supporting intelligent management. The main role is played by intelligent decision-making technologies. They make it possible, along with a decision or in the process of obtaining a decision, to search for new knowledge and accumulate intellectual resources. Information technologies create only information resources. This means that knowledge formalized in an explicit form, once mastered, can become part of experience and part of the knowledge base and be used by it to solve problems and make decisions.

Conclusion

Intelligent control is effective and necessary when managing complex objects for which it is difficult or impossible to find formal operating models. The basis of intelligent management is semiotic models in the first place and information models second. Intelligent control methods are diverse and applicable to technical, cognitive and transportation systems. Intelligent control is widely applied to multi-purpose control. Modern intelligent management is being integrated into cloud platforms and services. When managing distributed organizations and corporations, there is a need to take into account spatial relationships and spatial knowledge. Another problem is the limited number of intelligent technologies for working with tacit knowledge. Technically, the problem of knowledge management is related to the transformation of information resources into intellectual resources and their application in intelligent technologies.

Bibliography

- Pospelov D.A. Applied semiotics and artificial intelligence // Software products and systems. – 1996. – No. 3. – C.10-13

- Tsvetkov V.Ya. Cognitive control. Monograph - M.: MAKS Press, 2017. - 72 p. ISBN 978-5-317-05434-2

- Tsvetkov V.Ya. Information management. — LAP LAMBERT Academic Publishing GmbH & Co. KG, Saarbrücken, Germany 2012 -201с

- Osipov G.S. From situational management to applied semiotics. Artificial Intelligence News. 2002, no. 6.

- Nikiforov V. O., Slita O. V., Ushakov A. V. Intelligent control under conditions of uncertainty. - St. Petersburg: St. Petersburg State University ITMO, 2011.

- McAfee A., Brynjolfsson E. Big data: the management revolution //Harvard business review. – 2012. – No. 90. – pp. 60-6, 68, 128.

- Tsvetkov V.Ya. Markelov V.M., Romanov I.A. Overcoming information barriers // Distance and virtual learning. 2012. No. 11. P. 4-7.

- Forbes L. S., Kaiser G. W. Habitat choice in breeding seabirds: when to cross the information barrier //Oikos. – 1994. – P. 377-384.

- Tsvetkov V. Ya. Intelligent control technology. // Russian Journal of Sociology, 2015, Vol. (2), Is. 2.-р.97-104. DOI: 10.13187/rjs.2015.2.97 www.ejournal32.com.

- Zilouchian A., Jamshidi M. Intelligent control systems using soft computing methodologies. – CRC Press, Inc., 2000

- Alavi M., Leidner D. E. Review: Knowledge management and knowledge management systems: Conceptual foundations and research issues //MIS quarterly. – 2001. – p.107-136.

- Pospelov D.A. Modeling reasoning. Experience in analyzing mental acts. - M.: Radio and Communications, 1989. -184c.

- De Moura L., Bjørner N. Z3: An efficient SMT solver //Tools and Algorithms for the Construction and Analysis of Systems. – Springer Berlin Heidelberg, 2008. – pp. 337-340.

- Rosenberg I.N., Tsvetkov V.Ya. Application of multi-agent systems in intelligent logistics systems. // International Journal of Experimental Education. – 2012. – No. 6. – p.107-109

- Efimov E.I. Solver of intellectual problems - M.: Nauka, Main editorial office of physical and mathematical literature, 1982. - 320 p.

- Pospelov D.A., Osipov G.S. Applied semiotics // Artificial Intelligence News. - 1999. - No. 1.

- Tsvetkov V.Ya. Information uncertainty and certainty in the information sciences // Information technologies. - 2015. - No. 1. -p.3-7

- Tsvetkov V. Ya. Dichotomic Assessment of Information Situations and Information Superiority // European researcher. Series A. 2014, Vol.(86), No. 11-1, pp.1901-1909. DOI: 10.13187/er.2014.86.1901

- Tsvetkov V. Ya. Information Situation and Information Position as a Management Tool // European researcher. Series A. 2012, Vol.(36), 12-1, p.2166- 2170

- Tsvetkov V. Ya. Information Constructions // European Journal of Technology and Design. -2014, Vol (5), No. 3. - p.147-152

- 22. Pospelov D.A. Semiotic models: successes and prospects // Cybernetics. – 1976. – No. 6. – P.114-123.

- 23. Pospelov D.A. Semiotic models in management. Cybernetics. Practical matters. - M.: Nauka, 1984. – P.70-87

- Osipov G.S. et al. Intelligent control of vehicles: standards, projects, implementations // Aerospace instrumentation. – 2009. – No. 6. – pp. 34-43.

- Snytyuk V. E., Yurchenko K. N. Intelligent management of knowledge assessment // VE Snytyuk, KN Yurchenko. − Cherkassy. – 2013.

- Pugachev I. N., Markelov G. Ya. Intelligent management of urban transport systems // Transport and service: collection. scientific works.–Kaliningrad: Publishing house named after I. Kant. – 2014. – No. 2. – pp. 58-66.

- Atiencia V., Diveev A.I. Synthesis of an intelligent multi-purpose control system //Modern problems of science and education. – 2012. – No. 6.

- Gribova V.V. et al. Cloud platform for the development and management of intelligent systems // International scientific and technical conference “Open semantic technologies for the design of intelligent systems” (OSTIS-2011).-Minsk: BSUIR. – 2011. – P. 5-14.