Drinking cream. Specifications

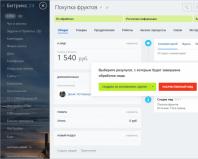

304.00 ₽

We have been distributing regulatory documents since 1999. We punch checks, pay taxes, accept all legal forms of payment without additional interest. Our clients are protected by law. LLC "CNTI Normocontrol"

Our prices are lower than other places because we work directly with document providers.

Delivery methods

- Express courier delivery (1-3 days)

- Courier delivery (7 days)

- Pickup from the Moscow office

- Russian Post

Applies to drinking cream packaged in consumer containers after heat treatment or heat-treated in consumer containers intended for direct use as food. The standard does not apply to products enriched with milk protein, vitamins, micro- and macroelements, dietary fiber, polyunsaturated fatty acids, phospholipids, probiotics and prebiotics.

Reissue. April 2014

1 area of use

3 Terms and definitions

4 Classification

5 Technical requirements

6 Acceptance rules

7 Control methods

This GOST is located in:

Organizations:

| 07.06.2013 | Approved | 43 | |

|---|---|---|---|

| 28.06.2013 | Approved | 269-st | |

| Published | 2014 | ||

| Published | 2013 | ||

| Designed by |

Normative references

- GOST 14192-96 Cargo marking

- GOST 26663-85 Transport packages. Formation using packaging tools. General technical requirements

- GOST 10970-87 Skimmed milk powder. Specifications

- GOST 1349-85 Canned milk. Dry cream. Specifications

- GOST 22280-76 Reagents. Sodium citrate 5.5-water. Specifications

- GOST 23285-78 Transport bags for food products and glass containers. Specifications

- GOST 23452-79 Milk and dairy products. Methods for determining residues of organochlorine pesticides. Replaced by GOST 23452-2015.

- GOST 2493-75 Reagents. Potassium phosphate disubstituted 3-water. Specifications

- GOST 25228-82 Milk and cream. Method for determining heat resistance using an alcohol test

- GOST 25776-83 Products are individual and in consumer packaging. Group packaging in shrink film

- GOST 26809-86 Milk and dairy products. Acceptance rules, sampling methods and sample preparation for analysis

- GOST 26927-86

- GOST 26932-86 Raw materials and food products. Lead determination methods

- GOST 26933-86 Raw materials and food products. Methods for determining cadmium

- GOST 28283-89 Cow's milk. Method for organoleptic evaluation of smell and taste. Replaced by GOST 28283-2015.

- GOST 30178-96 Raw materials and food products. Atomic absorption method for determining toxic elements

- GOST 30347-97 Milk and dairy products. Method for determining Staphylococcus aureus. Replaced by GOST 30347-2016.

- GOST 30519-97 Food products. Method for identifying bacteria of the genus Salmonella

- GOST 3622-68 Milk and dairy products. Sampling and preparing them for testing

- GOST 3623-73 Milk and dairy products. Methods for determining pasteurization. Replaced by GOST 3623-2015.

- GOST 3624-92 Milk and dairy products. Titrimetric methods for determining acidity

- GOST 4172-76 Reagents. Sodium phosphoric acid disubstituted 12-water. Specifications

- GOST 4495-87 Whole milk powder. Specifications

- GOST 5538-78 Reagents. Potassium citrate 1-water. Specifications

- GOST 5867-90 Milk and dairy products. Fat determination methods

- GOST 9225-84 Milk and dairy products. Microbiological analysis methods

- GOST R 51457-99 Cheese and processed cheese. Gravimetric method for determining the mass fraction of fat

- GOST 30711-2001 Food products. Methods for identifying and determining the content of aflatoxins B1 and M1

- GOST 30538-97 Food products. Methodology for determining toxic elements using the atomic emission method

- GOST 8.579-2002 State system for ensuring the uniformity of measurements. Requirements for the quantity of packaged goods in packages of any type during their production, packaging, sale and import

- GOST R 52791-2007 Canned milk. Powdered milk. Specifications

- GOST R 53430-2009 Milk and milk processing products. Microbiological analysis methods

- GOST R 53946-2010 Canned milk. Powdered milk for the production of baby food products. Specifications

- 005/2011 for Decision 769

- Technical regulations of the customs union 021/2011 for Decision 880

- Technical regulations of the customs union 022/2011 for Decision 881

- GOST R 55063-2012 Cheeses and processed cheeses. Acceptance rules, sampling and control methods

- GOST R 55361-2012 Milk fat, butter and butter paste from cow's milk. Acceptance rules, sampling and control methods

- GOST 31449-2013 Raw cow's milk. Specifications

page 1

page 2

page 3

page 4

page 5

page 6

page 7

page 8

page 9

page 10

page 11

INTERSTATE COUNCIL FOR STANDARDIZATION, METROLOGY AND CERTIFICATION

INTERSTATE COUNCIL FOR STANDARDIZATION, METROLOGY AND CERTIFICATION

INTERSTATE

STANDARD

GOST 31451-2013

2013

DRINKING CREAM Specifications

Official publication

|

Standardinform |

Preface

The goals, basic principles and basic procedure for carrying out work on interstate standardization are established by GOST 1.0-92 “Interstate standardization system. Basic provisions" and GOST 1.2-2009 "Interstate standardization system. Interstate standards, rules and recommendations for interstate standardization. Rules for development, adoption, application, updating and cancellation"

Standard information

1 DEVELOPED by the State Scientific Institution “All-Russian Research Institute of the Dairy Industry” of the Russian Academy of Agricultural Sciences (GNU VNIMI of the Russian Agricultural Academy)

2 INTRODUCED by the Federal Agency for Technical Regulation and Metrology

3 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (protocol dated June 7, 2013 No. 43)

|

4 By Order of the Federal Agency for Technical Regulation and Metrology dated June 28, 2013 No. 269-st, the interstate standard GOST 31451-2013 was put into effect as a national standard of the Russian Federation on July 1, 2014.

5 This standard has been prepared based on the application of GOST R 52091-2003

6 INTRODUCED FOR THE FIRST TIME

7 REPUBLICATION. April 2014

Information about changes to this standard is published in the annual information index “National Standards”, and the text of changes and amendments is published in the monthly information index “National Standards”. In case of revision (replacement) or cancellation of this standard, the corresponding notice will be published in the monthly information index “National Standards”. Relevant information, notifications and texts are also posted in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet

© Standardinform, 2014

In the Russian Federation, this standard cannot be fully or partially reproduced, replicated and distributed as an official publication without permission from the Federal Agency for Technical Regulation and Metrology

Editor M.I. Maksimova Technical editor V.N. Prusakova Proofreader E.D. Dulneva Computer layout V.I. Goishchenko

Signed for publication on June 2, 2014. Format bОхвД^в. Arial typeface. Uel. oven l. 1.40. Academic ed. l. 0.85. Circulation 29 copies. Zach. 2222.

Published and printed by FSUE STANDARDINFORM, 123995 Moscow, Granatny per., 4. www.gostinfo.ru [email protected]

INTERSTATE STANDARD

DRINKING CREAM Technical specifications

Drinking cream. Specifications

Date of introduction* - 2014-07-01

1 area of use

This standard applies to drinking cream packaged in consumer containers after heat treatment or heat-treated in consumer containers (hereinafter referred to as the product) intended for direct use as food.

This standard does not apply to products enriched with milk protein, vitamins, micro- and macroelements, dietary fiber, polyunsaturated fatty acids, phospholipids, probiotics and prebiotics.

Requirements ensuring product safety are set out in 5.1.4, 5.1.5, quality requirements - in 5.1.2, 5.1.3, labeling requirements - in 5.3.

2 Normative references

This standard uses normative references to the following interstate standards:

*** Application on the territory of the Russian Federation in terms of section. 4, from 01.07.2002 to use GOST R 51457-99. The use of rennet and processed cheeses on the territory of the Russian Federation has been discontinued; from 01/01/2014, use of GOST R 55063-2012. The use in the territory of the Russian Federation in terms of butter without fillers, butter with fillers, salted butter has been discontinued; from 01/01/2014, use of GOST 55361-2012.

* 4 GOST R 53430-2009 is in force on the territory of the Russian Federation.

* 5 GOST R 52791-2007 is in force on the territory of the Russian Federation.

|

Table 1 |

||||||||||

|

5.1.3 In terms of physical and chemical indicators, the product must comply with the standards specified in Table 2.

|

table 2 |

|||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

5.1.4 Permissible levels of potentially hazardous substances (toxic elements, mycotoxins, dioxins, melamine, antibiotics, pesticides, radionuclides) in the product must not exceed the requirements.

5.1.5 Permissible levels of microorganisms (QMAFAnM, coliforms, pathogenic microorganisms, including salmonella, staphylococcus S.aureus, listeria L.monocytogenes) in pasteurized and ultra-pasteurized products without aseptic filling should not exceed the requirements.

5.1.6 Sterilized and ultra-pasteurized products with aseptic filling must meet the requirements of industrial sterility established by regulations in force in the territory of the states that have adopted the standard.

5.2 Requirements for raw materials

5.2.1 The following raw materials are used for the manufacture of pasteurized product:

Skimmed milk is a raw material according to regulatory and technical documents in force in the countries that have adopted the standard;

Cream - raw materials according to regulatory and technical documents in force in the countries that have adopted the standard;

Skimmed milk powder according to GOST 10970;

Sodium phosphate disubstituted 12-water according to GOST 4172.

5.2.3 The raw materials used to manufacture the product must meet the safety requirements.

5.2.4 It is allowed to use similar raw materials of domestic and other production that are not inferior in quality and safety indicators specified in 5.2.1-5.2.3.

5.3 Marking

5.3.1 Labeling of consumer packaging is carried out in accordance with.

5.3.2 Marking of group packaging, reusable and transport containers, transport package - in accordance with the application of handling signs or warning labels: “Keep away from sunlight” and “Temperature limit” indicating the minimum and maximum temperature values according to GOST 14192, regulatory and technical documents valid in the territory of the states that have adopted the standard.

5.3.3 When banding with transparent polymeric materials, markings may not be applied to the side surfaces of the group packaging, transport containers and transport package. In this case, markings are visible inscriptions on consumer packaging or group packaging, or transport packaging, supplemented by information on the number of pieces and gross weight. Non-visible inscriptions, including manipulation marks, are applied to insert sheets or presented in any other available way.

5.4 Packaging

5.4.1 Containers and materials used for packaging and sealing the product must comply with the requirements of the documents in accordance with which they are manufactured, and ensure the preservation of the quality and safety of the products during their transportation, storage and sale.

5.4.2 Formation of group packaging - in accordance with GOST 25776.

5.4.3 Transport packages are formed in accordance with GOST 23285 and GOST 26663.

5.4.4 The transport package is laid out so that the marking of at least one unit of consumer packaging and/or group packaging, and/or transport packaging, and/or reusable packaging is visible on each side of the transport package.

The transport package is laid in ways that ensure the safety of the bottom rows of consumer packaging and/or group packaging, and/or shipping packaging, and/or reusable packaging without deformation.

5.4.5 Permissible negative deviations of the net content from the nominal quantity - in accordance with GOST 8.579.

6 Acceptance rules

7.13 Determination of the content of GMOs, melamine, dioxins (in case of a reasonable assumption of their possible presence) - according to regulatory documents in force in the territory of the states that have adopted the standard.

7.14 Determination of microbiological indicators:

KMAFAnM, coliforms (coliforms) - according to GOST 9225

S.aureus - according to GOST 30347 and regulatory documents in force in the countries that have adopted the standard;

Pathogenic microorganisms, including salmonella, - according to GOST 30519 and regulatory documents in force in the countries that have adopted the standard;

Listeria L.monocytogenes - according to regulatory documents in force in the territory of states that have adopted the standard.

8 Transportation and storage

8.1 The product is transported by specialized vehicles in accordance with the rules for the transportation of perishable goods in force for this type of transport.

8.2 Pasteurized and ultra-pasteurized product (without aseptic filling) is stored at a temperature of (4 + 2) °C.

Sterilized and ultra-pasteurized product (with aseptic filling) is stored at a temperature from 2 ° C to 25 ° C.

The shelf life of the product from the end of the technological process is set by the manufacturer, taking into account the requirements of regulatory legal acts in the field of food safety.

Bibliography

Technical Regulations of the Customs Union TR CU 021/2011 Technical Regulations of the Customs Union TR CU 022/2011 Technical Regulations of the Customs Union TR CU 005/2011

“On the safety of food products” “Food products in terms of their labeling” “On the safety of packaging”

UDC 637.14:006.354 MKS 67.100.10 N17

Key words: drinking cream, scope of application, regulatory references, classification, technical requirements, safety requirements, acceptance rules, control methods, transportation, storage

Drinking cream, GOST R 52091-2003

Food production. GOST R 52091-2003: Drinking cream. Technical conditions. OKS: Food production, Milk and dairy products. GOST standards. Drinking cream. Technical conditions. class=text>

GOST R 52091-2003

Drinking cream. Specifications

GOST R 52091-2003

Group H17

STATE STANDARD OF THE RUSSIAN FEDERATION

DRINKING CREAM

Specifications

Drinking cream. Specifications

OKS 67.100.10

OKP 92 2200

Date of introduction 2004-07-01

Preface

1 DEVELOPED by the State Scientific Institution All-Russian Scientific Research Institute of the Dairy Industry (GNU VNIMI) with the participation of the Institute of Nutrition of the Russian Academy of Medical Sciences, the Russian Union of Dairy Enterprises (RSDMO), OJSC "OCHAKOVSKY DAIRY PLANT", OJSC "CHERKIZOVSKY DAIRY PLANT", OJSC "OBNINSKY DAIRY PLANT" ", LLC "RostAgroKomplekt", CJSC "VALIO SAINT-PETERSBURG", OJSC Smolensk Dairy Plant "ROSA", OJSC "PETMOL. St. Petersburg DAIRY PLANT N 1, LLC "DANON INDUSTRY", LLC "Hr.HANSEN" by order of the National Consumer Protection Fund (Russia)

INTRODUCED by the Technical Committee for Standardization TC 186 "Milk and Dairy Products"

2 ADOPTED AND ENTERED INTO EFFECT by Resolution of the State Standard of Russia dated June 30, 2003 N 220-st

3 INTRODUCED FOR THE FIRST TIME

AMENDED Change No. 1, approved and put into effect by Order of the Federal Agency for Technical Regulation and Metrology dated 12/09/2008 N 375-st from 07/01/2009

Change No. 1 was made by the database manufacturer according to the text of IUS No. 2, 2009

1 area of use

1 area of use

This standard applies to drinking cream packaged in consumer containers after heat treatment or heat-treated in consumer containers (hereinafter referred to as the product), made from cow's milk and/or dairy products, intended for direct use as food.

This standard does not apply to products enriched with vitamins, micro- and macroelements, probiotic cultures and prebiotic substances.

Safety requirements are set out in 5.4-5.7, 5.9.1, quality requirements - in 5.2-5.3, labeling requirements - in 5.8.

2 Normative references

This standard uses references to the following standards:

GOST 8.579-2002 State system for ensuring the uniformity of measurements. Requirements for the quantity of packaged goods in packages of any type during production, packaging, sale and import

GOST 37-91 Cow butter. Specifications

GOST 1349-85 Canned milk. Dry cream. Specifications

GOST 2493-75 Potassium phosphate, disubstituted 3-water. Specifications

GOST 3622-68 Milk and dairy products. Sampling and preparing them for testing

GOST 3623-73 Milk and dairy products. Methods for determining pasteurization

GOST 3624-92 Milk and dairy products. Titrimetric methods for determining acidity

GOST 4172-76 Sodium phosphate disubstituted 12-water. Specifications

GOST 5538-78 Potassium citrate 1-water. Specifications

GOST 5867-90 Milk and dairy products. Fat determination methods

GOST 14192-96 Marking of cargo

GOST 15846-2002 Products sent to the Far North and equivalent areas. Packaging, labeling, transportation and storage

GOST 17527-2003 Packaging. Terms and Definitions

GOST 22280-76 Sodium citrate 5.5-aqueous. Specifications

GOST 23285-78 Transport bags for food products and glass containers. Specifications

GOST 23327-98 Milk and dairy products. Method for measuring the mass fraction of total nitrogen according to Kjeldahl and determining the mass fraction of protein

GOST 25228-82 Milk and cream. Method for determining heat resistance using an alcohol test

GOST 25776-83 Piece products and in consumer packaging. Group packaging in shrink film

GOST 26663-85 Transport packages. Formation using packaging tools. General technical requirements

GOST 26809-86 Milk and dairy products. Acceptance rules, sampling methods and sample preparation for analysis

GOST 30648.2-99 Dairy products for baby food. Methods for determining total protein

GOST R 51474-99 Packaging. Markings indicating how the goods are handled

GOST R 52054-2003 Natural cow's milk - raw material. Specifications

GOST R 52738-2007 Milk and milk processing products. Terms and Definitions

GOST R 52791-2007 Canned milk. Powdered milk. Specifications

SanPiN 2.1.4.1074-2001 Drinking water. Hygienic requirements for water quality of centralized drinking water supply systems. Quality control

(Changed edition, Amendment No. 1).

3 Definitions

This standard uses the following terms: according to GOST R 52738, according to GOST 17527 - clause 5.9.

(Changed edition, Amendment No. 1).

4 Classification

Depending on the heat treatment mode, the product is divided into:

- pasteurized;

- sterilized;

- ultra-pasteurized.

Section 4. (Changed edition, Amendment No. 1).

5 General technical requirements

5.1 The product is manufactured in accordance with the requirements of this standard according to technological instructions approved in the prescribed manner.

5.2 In terms of organoleptic characteristics, the product must meet the requirements of Table 1.

Table 1

Indicator name | Characteristic |

Appearance | Homogeneous opaque liquid. Minor fat sediment is allowed, disappearing with stirring. |

Consistency | Homogeneous, moderately viscous. Free from protein flakes and lumps of fat |

Taste and smell | Characteristic of cream, without foreign tastes and odors, with a slight aftertaste of boiling. For a product made from recombined cream, a sweetish-salty flavor is allowed |

White with a creamy tint, uniform throughout the mass |

5.3 In terms of physical and chemical indicators, the product must comply with the standards specified in Table 3.

Table 3*

______________

* Tayul.2. Deleted, Change N 1.

Indicator name | Standard for a product with a mass fraction of fat, %, not less |

||||

10,0; 11,0; 12,0; 13,0; 14,0; 15,0; 16,0; 17,0; 18,0 | 19,0; 20,0; 21,0; 22,0; 23,0; 24,0 | 25,0; 26,0; 27,0; 28,0 | 29,0; 30,0; 31,0; 32,0; 33,0; 34,0 | 35,0; 36,0; 37,0; 38,0; 39,0; 40,0; 41,0; 42,0 |

|

Mass fraction of protein, %, not less | |||||

Acidity, °T, no more | |||||

Temperature of the product upon release from the enterprise, °C | |||||

for pasteurized | |||||

for UHT and sterilized | |||||

5.5 Microbiological indicators of the product must comply with the requirements of regulatory legal acts of the Russian Federation.

5.6 The efficiency indicators of heat treatment of the product must comply with the requirements established in the regulatory legal acts of the Russian Federation.

5.2-5.6 (Changed edition, Amendment No. 1).

5.7 Requirements for raw materials

5.7.1 The following raw materials are used for the manufacture of pasteurized product:

- cow's milk is not lower than first grade according to GOST R 52054;

- dry cream according to GOST 1349;

5.7.2 For the manufacture of sterilized and ultra-pasteurized products, the following raw materials are used:

- cow's milk is not lower than the first grade according to GOST R 52054 with a somatic cell content of no more than 500 thousand/cm, and heat resistance according to the alcohol test is not lower than the second group according to GOST 25228;

- milk powder according to GOST R 52791;

- dry cream according to GOST 1349, premium grade, acidity from 15 to 18 °T, heat resistance according to alcohol test after reconstitution is not lower than the second group according to GOST 25228;

- unsalted butter according to GOST 37;

Drinking water according to SanPiN 2.1.4.1074 (for reconstituted and recombined cream).

5.7.3 For ultra-pasteurized and sterilized products, it is allowed to use stabilizer salts:

- sodium citrate 5.5-water according to GOST 22280;

Potassium citrate trisubstituted 1-water according to GOST 5538;

- potassium phosphate disubstituted 3-water according to GOST 2493;

- sodium phosphate disubstituted 12-water according to GOST 4172.

5.7.1-5.7.3 (Changed edition, Amendment No. 1).

5.7.4 The raw materials used for the manufacture of the product in terms of safety indicators must comply with the requirements of regulatory legal acts of the Russian Federation, SanPiN 2.1.4.1074.

(Changed edition, Amendment No. 1).

5.7.5 It is allowed to use other raw materials that, in terms of quality and safety, are not inferior to the requirements specified in 5.7.1-5.7.4 and are permitted for use in the prescribed manner, and do not change the nature of the product.

(Changed edition, Amendment No. 1).

5.8 Marking

5.8.1 Labeling of consumer packaging, group packaging, transport packaging, reusable packaging, transport package in accordance with regulatory legal acts of the Russian Federation.

(Changed edition, Amendment No. 1).

5.8.2-5.8.4 (Deleted, Amendment No. 1).

5.8.5 Handling signs are applied to the transport container in accordance with GOST 14192, GOST R 51474: “Keep away from sunlight”, “Temperature limit” indicating the minimum and maximum temperature values.

(Changed edition, Amendment No. 1).

5.8.6 When banding with transparent polymeric materials, markings on the side surfaces of group packaging and transport containers according to 5.8.2 and transport package according to 5.8.4 may not be applied. In this case, markings are visible inscriptions on consumer packaging or group packaging, or transport packaging, supplemented by information on the number of pieces and gross weight. Non-visible inscriptions, including manipulation marks, are applied to insert sheets or presented in any other available way.

5.8.7 Information data is indicated in Russian and additionally, if necessary, in the state languages of the constituent entities of the Russian Federation, native languages of the peoples of the Russian Federation, as well as foreign languages.

5.9 Packaging

5.9.1 Containers and materials used for packaging and sealing the product must comply with the requirements of legislative, regulatory and/or technical documents establishing the possibility of their use for packaging dairy products.

5.9.2 Transport packages are formed in accordance with GOST 23285, GOST 26663.

(Changed edition, Amendment No. 1).

5.9.3 The transport package is laid out so that the marking of at least one unit of consumer packaging and/or group packaging, and/or transport packaging, and/or reusable packaging is visible on each side of the transport package.

The transport package is laid in ways that ensure the safety of the bottom rows of consumer packaging and/or group packaging, and/or shipping packaging, and/or reusable packaging without deformation.

5.9.4 Permissible negative deviations of the net content from the nominal quantity (no more than 10 kg) - in accordance with GOST 8.579.

(Changed edition, Amendment No. 1).

5.9.5 Formation of group packaging - in accordance with GOST 25776.

(Introduced additionally, Amendment No. 1).

6 Acceptance rules

6.1 Acceptance rules - according to GOST 26809.

6.2 Each batch of product is controlled according to the quality and safety indicators established in section 5, with the frequency established in the production control program.

(Changed edition, Amendment No. 1).

6.3 The procedure and frequency of monitoring the content of chemical and microbiological contaminants is established by the manufacturer in the production control program approved in the prescribed manner.

7 Control methods

7.1 Sampling and preparing them for analysis - according to GOST 3622, GOST 26809.

7.2 Determination of appearance, consistency, taste and smell, color is carried out organoleptically and characterized in accordance with the requirements of 5.2.

7.3 Determination of the temperature of the product upon release from the enterprise and the mass of the product - according to GOST 3622.

7.4 Determination of the mass fraction of fat - according to GOST 5867.

7.5 Determination of the mass fraction of protein - according to GOST 23327, GOST 30648.2.

(Changed edition, Amendment No. 1).

7.6 Determination of acidity - according to GOST 3624.

7.7 Determination of efficiency indicators of heat treatment of the product - according to GOST 3623.

(Changed edition, Amendment No. 1).

7.8 Determination of the content of toxic elements, mycotoxins, antibiotics, pesticides is carried out by methods provided for by regulatory documents and according to methods approved in the prescribed manner.

7.9 Determination of radionuclides is carried out according to methods approved in accordance with the established procedure.

7.10 Determination of microbiological indicators is carried out using methods provided for in regulatory documents and according to methods approved in the prescribed manner.

7.8-7.10 (Changed edition, Amendment No. 1).

8 Transportation and storage

8.1 The product is transported by specialized vehicles in accordance with the rules for the transportation of perishable goods in force for this type of transport.

8.2 Storage conditions and shelf life of the product are established by the manufacturer.

Jalapeno M Pepper Seeds 100 SEEDS NON-GMO

| $2.49 End Date: Saturday Jul-27-2019 18:12:47 PDT Buy It Now for only: $2.49 | |

| $2.49 End Date: Thursday Aug-29-2019 15:44:42 PDT Buy It Now for only: $2.49 | |

GOST R 52091-2003

Group H17

STATE STANDARD OF THE RUSSIAN FEDERATION

DRINKING CREAM

Specifications

Drinking cream. Specifications

OKS 67.100.10

OKP 92 2200

Date of introduction 2004-07-01

Preface

1 DEVELOPED by the State Scientific Institution All-Russian Scientific Research Institute of the Dairy Industry (GNU VNIMI) with the participation of the Institute of Nutrition of the Russian Academy of Medical Sciences, the Russian Union of Dairy Enterprises (RSDMO), OJSC "OCHAKOVSKY DAIRY PLANT", OJSC "CHERKIZOVSKY DAIRY PLANT", OJSC "OBNINSKY DAIRY PLANT" ", LLC "RostAgroKomplekt", CJSC "VALIO SAINT-PETERSBURG", OJSC Smolensk Dairy Plant "ROSA", OJSC "PETMOL. St. Petersburg DAIRY PLANT N 1, LLC "DANON INDUSTRY", LLC "Hr.HANSEN" by order of the National Consumer Protection Fund (Russia)

INTRODUCED by the Technical Committee for Standardization TC 186 "Milk and Dairy Products"

2 ADOPTED AND ENTERED INTO EFFECT by Resolution of the State Standard of Russia dated June 30, 2003 N 220-st

3 INTRODUCED FOR THE FIRST TIME

AMENDED Change No. 1, approved and put into effect by Order of the Federal Agency for Technical Regulation and Metrology dated 12/09/2008 N 375-st from 07/01/2009

Change No. 1 was made by the database manufacturer according to the text of IUS No. 2, 2009

1 area of use

1 area of use

This standard applies to drinking cream packaged in consumer containers after heat treatment or heat-treated in consumer containers (hereinafter referred to as the product), made from cow's milk and/or dairy products, intended for direct use as food.

This standard does not apply to products enriched with vitamins, micro- and macroelements, probiotic cultures and prebiotic substances.

Safety requirements are set out in 5.4-5.7, 5.9.1, quality requirements - in 5.2-5.3, labeling requirements - in 5.8.

2 Normative references

This standard uses references to the following standards:

GOST 8.579-2002 State system for ensuring the uniformity of measurements. Requirements for the quantity of packaged goods in packages of any type during production, packaging, sale and import

GOST 37-91 Cow butter. Specifications

GOST 1349-85 Canned milk. Dry cream. Specifications

GOST 2493-75 Potassium phosphate, disubstituted 3-water. Specifications

GOST 3622-68 Milk and dairy products. Sampling and preparing them for testing

GOST 3623-73 Milk and dairy products. Methods for determining pasteurization

GOST 3624-92 Milk and dairy products. Titrimetric methods for determining acidity

GOST 4172-76 Sodium phosphate disubstituted 12-water. Specifications

GOST 5538-78 Potassium citrate 1-water. Specifications

GOST 5867-90 Milk and dairy products. Fat determination methods

GOST 14192-96 Marking of cargo

GOST 15846-2002 Products sent to the Far North and equivalent areas. Packaging, labeling, transportation and storage

GOST 17527-2003 Packaging. Terms and Definitions

GOST 22280-76 Sodium citrate 5.5-aqueous. Specifications

GOST 23285-78 Transport bags for food products and glass containers. Specifications

GOST 23327-98 Milk and dairy products. Method for measuring the mass fraction of total nitrogen according to Kjeldahl and determining the mass fraction of protein

GOST 25228-82 Milk and cream. Method for determining heat resistance using an alcohol test

GOST 25776-83 Piece products and in consumer packaging. Group packaging in shrink film

GOST 26663-85 Transport packages. Formation using packaging tools. General technical requirements

GOST 26809-86 Milk and dairy products. Acceptance rules, sampling methods and sample preparation for analysis

GOST 30648.2-99 Dairy products for baby food. Methods for determining total protein

GOST R 51474-99 Packaging. Markings indicating how the goods are handled

GOST R 52054-2003 Natural cow's milk - raw material. Specifications

GOST R 52738-2007 Milk and milk processing products. Terms and Definitions

GOST R 52791-2007 Canned milk. Powdered milk. Specifications

SanPiN 2.1.4.1074-2001 Drinking water. Hygienic requirements for water quality of centralized drinking water supply systems. Quality control

(Changed edition, Amendment No. 1).

3 Definitions

This standard uses the following terms: according to GOST R 52738, according to GOST 17527 - clause 5.9.

(Changed edition, Amendment No. 1).

4 Classification

Depending on the heat treatment mode, the product is divided into:

- pasteurized;

- sterilized;

- ultra-pasteurized.

Section 4. (Changed edition, Amendment No. 1).

5 General technical requirements

5.1 The product is manufactured in accordance with the requirements of this standard according to technological instructions approved in the prescribed manner.

5.2 In terms of organoleptic characteristics, the product must meet the requirements of Table 1.

Table 1

Indicator name | Characteristic |

Appearance | Homogeneous opaque liquid. Minor fat sediment is allowed, disappearing with stirring. |

Consistency | Homogeneous, moderately viscous. Free from protein flakes and lumps of fat |

Taste and smell | Characteristic of cream, without foreign tastes and odors, with a slight aftertaste of boiling. For a product made from recombined cream, a sweetish-salty flavor is allowed |

White with a creamy tint, uniform throughout the mass |

5.3 In terms of physical and chemical indicators, the product must comply with the standards specified in Table 3.

Table 3*

______________

* Tayul.2. Deleted, Change N 1.

Indicator name | Standard for a product with a mass fraction of fat, %, not less |

||||

10,0; 11,0; 12,0; 13,0; 14,0; 15,0; 16,0; 17,0; 18,0 | 19,0; 20,0; 21,0; 22,0; 23,0; 24,0 | 25,0; 26,0; 27,0; 28,0 | 29,0; 30,0; 31,0; 32,0; 33,0; 34,0 | 35,0; 36,0; 37,0; 38,0; 39,0; 40,0; 41,0; 42,0 |

|

Mass fraction of protein, %, not less | |||||

Acidity, °T, no more | |||||

Temperature of the product upon release from the enterprise, °C | |||||

for pasteurized | |||||

for UHT and sterilized | |||||

5.5 Microbiological indicators of the product must comply with the requirements of regulatory legal acts of the Russian Federation.

5.6 The efficiency indicators of heat treatment of the product must comply with the requirements established in the regulatory legal acts of the Russian Federation.

5.2-5.6 (Changed edition, Amendment No. 1).

5.7 Requirements for raw materials

5.7.1 The following raw materials are used for the manufacture of pasteurized product:

- cow's milk is not lower than first grade according to GOST R 52054;

- dry cream according to GOST 1349;

5.7.2 For the manufacture of sterilized and ultra-pasteurized products, the following raw materials are used:

- cow's milk is not lower than the first grade according to GOST R 52054 with a somatic cell content of no more than 500 thousand/cm, and heat resistance according to the alcohol test is not lower than the second group according to GOST 25228;

- milk powder according to GOST R 52791;

- dry cream according to GOST 1349, premium grade, acidity from 15 to 18 °T, heat resistance according to alcohol test after reconstitution is not lower than the second group according to GOST 25228;

- unsalted butter according to GOST 37;

Drinking water according to SanPiN 2.1.4.1074 (for reconstituted and recombined cream).

5.7.3 For ultra-pasteurized and sterilized products, it is allowed to use stabilizer salts:

- sodium citrate 5.5-water according to GOST 22280;

Potassium citrate trisubstituted 1-water according to GOST 5538;

- potassium phosphate disubstituted 3-water according to GOST 2493;

- sodium phosphate disubstituted 12-water according to GOST 4172.

5.7.1-5.7.3 (Changed edition, Amendment No. 1).

5.7.4 The raw materials used for the manufacture of the product in terms of safety indicators must comply with the requirements of regulatory legal acts of the Russian Federation, SanPiN 2.1.4.1074.

(Changed edition, Amendment No. 1).

5.7.5 It is allowed to use other raw materials that, in terms of quality and safety, are not inferior to the requirements specified in 5.7.1-5.7.4 and are permitted for use in the prescribed manner, and do not change the nature of the product.

(Changed edition, Amendment No. 1).

5.8 Marking

5.8.1 Labeling of consumer packaging, group packaging, transport packaging, reusable packaging, transport package in accordance with regulatory legal acts of the Russian Federation.

(Changed edition, Amendment No. 1).

5.8.2-5.8.4 (Deleted, Amendment No. 1).

5.8.5 Handling signs are applied to the transport container in accordance with GOST 14192, GOST R 51474: “Keep away from sunlight”, “Temperature limit” indicating the minimum and maximum temperature values.

(Changed edition, Amendment No. 1).

5.8.6 When banding with transparent polymeric materials, markings on the side surfaces of group packaging and transport containers according to 5.8.2 and transport package according to 5.8.4 may not be applied. In this case, markings are visible inscriptions on consumer packaging or group packaging, or transport packaging, supplemented by information on the number of pieces and gross weight. Non-visible inscriptions, including manipulation marks, are applied to insert sheets or presented in any other available way.

5.8.7 Information data is indicated in Russian and additionally, if necessary, in the state languages of the constituent entities of the Russian Federation, native languages of the peoples of the Russian Federation, as well as foreign languages.

5.9 Packaging

5.9.1 Containers and materials used for packaging and sealing the product must comply with the requirements of legislative, regulatory and/or technical documents establishing the possibility of their use for packaging dairy products.

5.9.2 Transport packages are formed in accordance with GOST 23285, GOST 26663.

(Changed edition, Amendment No. 1).

5.9.3 The transport package is laid out so that the marking of at least one unit of consumer packaging and/or group packaging, and/or transport packaging, and/or reusable packaging is visible on each side of the transport package.

The transport package is laid in ways that ensure the safety of the bottom rows of consumer packaging and/or group packaging, and/or shipping packaging, and/or reusable packaging without deformation.

5.9.4 Permissible negative deviations of the net content from the nominal quantity (no more than 10 kg) - in accordance with GOST 8.579.

(Changed edition, Amendment No. 1).

5.9.5 Formation of group packaging - in accordance with GOST 25776.

(Introduced additionally, Amendment No. 1).

6 Acceptance rules

6.1 Acceptance rules - according to GOST 26809.

6.2 Each batch of product is controlled according to the quality and safety indicators established in section 5, with the frequency established in the production control program.

(Changed edition, Amendment No. 1).

6.3 The procedure and frequency of monitoring the content of chemical and microbiological contaminants is established by the manufacturer in the production control program approved in the prescribed manner.

7 Control methods

7.1 Sampling and preparing them for analysis - according to GOST 3622, GOST 26809.

7.2 Determination of appearance, consistency, taste and smell, color is carried out organoleptically and characterized in accordance with the requirements of 5.2.

7.3 Determination of the temperature of the product upon release from the enterprise and the mass of the product - according to GOST 3622.

7.4 Determination of the mass fraction of fat - according to GOST 5867.

7.5 Determination of the mass fraction of protein - according to GOST 23327, GOST 30648.2.

(Changed edition, Amendment No. 1).

7.6 Determination of acidity - according to GOST 3624.

7.7 Determination of efficiency indicators of heat treatment of the product - according to GOST 3623.

(Changed edition, Amendment No. 1).

7.8 Determination of the content of toxic elements, mycotoxins, antibiotics, pesticides is carried out by methods provided for by regulatory documents and according to methods approved in the prescribed manner.

7.9 Determination of radionuclides is carried out according to methods approved in accordance with the established procedure.

7.10 Determination of microbiological indicators is carried out using methods provided for in regulatory documents and according to methods approved in the prescribed manner.

7.8-7.10 (Changed edition, Amendment No. 1).

8 Transportation and storage

8.1 The product is transported by specialized vehicles in accordance with the rules for the transportation of perishable goods in force for this type of transport.

8.2 Storage conditions and shelf life of the product are established by the manufacturer.

ROSSTANDART

FA on technical regulation and metrology

NEW NATIONAL STANDARDS

www.protect.gost.ru

FSUE STANDARDINFORM

provision of information from the "Products of Russia" database

www.gostinfo.ru

FA ON TECHNICAL REGULATION

Information system "Dangerous goods"

www.sinatra-gost.ru

Factors shaping quality. Product quality is one of the most important factors in the effective economic activity of any enterprise or organization. The quality of a food product is a set of product properties determined by its suitability to meet certain needs in accordance with its intended purpose. The quality must meet the requirements of the standards. For cream: the taste and smell must be pure, without foreign tastes and odors, with a pronounced taste of pasteurization; the consistency is homogeneous, without stray lumps of fat and protein flakes; color white with a yellowish tint; Cream with defects: bitter, rancid, fodder flavors and viscous consistency are not allowed for sale. Quality is affected by various interdependent activities at different stages - from identifying needs to assessing their satisfaction. These stages and activities in accordance with ISO recommendations include: marketing (search and market research); design and development of technical requirements, product development (normative documentation); logistics (raw materials, materials)

Table 1.Organoleptic characteristics of drinking cream

|

Characteristic name | |

|

Appearance |

Homogeneous opaque liquid. A slight sediment of fat is allowed, which disappears with stirring. |

|

Consistency |

Homogeneous, moderately viscous. Without protein flakes and fat lumps. |

|

Taste and smell |

Clean, fresh, slightly sweet, characteristic of cream, without foreign tastes or odors, with a slight aftertaste of boiling. For a product made from reconstituted cream, a sweetish-salty flavor is allowed. |

|

White with a creamy tint, uniform throughout the mass |

In terms of microbiological indicators, cream must meet the requirements of SanPiN “Hygienic Safety Requirements”, 2002. In pasteurized cream in consumer packaging, the presence of coliforms of 0.01 g is not allowed. Cream sterilized in consumer containers must meet the requirements of industrial sterility.

The milk should be a homogeneous liquid without sediment. Milk with high fat content should not have cream sediment. TASTE AND SMELL must be clean, without extraneous tastes and odors that are not characteristic of fresh milk.

The COLOR is WHITE, with a slightly yellowish tint, for melted - with a creamy tint, for non-greasy - with a slightly bluish tint.

DEFECTS OF MILK. Defects found in milk are caused by various reasons, feed, improper milk processing technology, and violation of storage conditions and periods. - TASTE DEFECTS easily arise under the influence of bacterial processes. So: - sour taste appears as a result of the activity of lactic acid bacteria; - bitter - during long-term storage of milk at temperatures below 10 degrees due to the development of putrefactive microorganisms; - milk acquires a soapy taste during long-term storage, when as a result of the development of putrefactive microflora, alkaline substances are formed that wash the fat; - unpleasant tastes in milk can appear from feeding animals fresh nettle, sedge, cabbage, garlic, turnips, etc. - a salty taste is formed due to some diseases of the animal's udder. - ODOR DEFECTS are most often caused by specific odors of feed or occur when milk is stored in open containers in rooms where pungently smelling products are stored. Of the discreditable odors, the most famous are bread, garlic, cheese, etc. CONSISTENCY DEFECTS are formed as a result of the activity of certain microorganisms. Milk acquires a THICK CONSISTENCY due to the activity of lactic acid bacteria, and a MUCINOUS or stringy consistency due to the action of mucus-forming microorganisms. As a result of the development of yeast, E. coli and butyric acid bacteria, FOAM is formed in milk. When freezing, the colloidal state of milk is disrupted, as a result of which it stratifies - desalinated ice forms on the walls of the container, fat floats to the surface, and protein concentrates in the central and lower parts. When milk thaws, flakes and lumps form. COLOR DEFECTS appear under the influence of pigmenting bacteria, causing redness, blueness and yellowing of milk. The reason for the color change may also be the presence of a certain amount of blood that got into the milk during milking due to the painful condition of the animal.

Table 2. According to physical and chemical indicators, drinking cream must meet the following requirements:

|

Indicator name |

Values of physical and chemical parameters |

||||

|

Low-fat |

Low fat |

Classic |

High fat |

||

|

Mass fraction of protein, %, not less | |||||

|

Acidity, about T, no more |

From 17.0 to 19.0 |

From 16.5 to 18.5 |

From 15.5 to 17.5 |

From 13.5 to 15.5 |

From 12.5 to 14.5 |

|

Temperature at release from the enterprise, o C: - for thermized, pasteurized and UHT - processed cream | |||||

|

For sterilized and UHT-treated sterilized cream | |||||

For drinking cream, whole milk is used that is not lower than grade 1 of the current standard for raw milk, with an acidity not higher than 18°T, grade 1 and 2 cream, with an acidity of 14°T with a fat content of 32 to 37% for grade 1 and 17°T - for the 2nd. In addition, whole milk powder, skimmed milk powder, dry cream, unsalted butter, vitamins, vitamin and multivitamin premixes, probiotic substances, micro- and macroelements, and drinking water are used to produce drinking cream. For UHT-treated and sterilized cream, whole milk powder must be of the highest grade, with an acidity in the reconstituted version of no more than 18T and a heat resistance of at least group 2 according to the alcohol test. To produce sterilized cream and UHT-processed cream, whole milk must contain no more than 500 thousand somatic cells/cm 3 . In order to preserve the quality of sterilized cream, UHT-treated cream, UHT-treated sterilized cream, the use of stabilizer salts in the form of sodium and potassium citrate or sodium and potassium phosphate is allowed. To manufacture the product, it is allowed to use not only domestic but also imported raw materials that meet the specified requirements of the standard for raw materials in terms of quality and safety. The technological process for the production of cream is similar to the process for the production of drinking milk and includes the following operations: quality assessment and acceptance of milk, cleaning, cooling, reserving, separating milk to obtain cream, fat normalization, homogenization, pasteurization, cooling, packaging and storage. The cream mixture normalized for fat is homogenized at a temperature of 55-50°C and a pressure of 5 to 10 MPa, depending on its fat content. Cream is pasteurized at a temperature higher than milk for the following reasons. During pasteurization, fat globules warm up more slowly than plasma and can have a protective effect on microorganisms. Therefore, the higher the fat content of the cream, the higher the pasteurization temperature should be. Pasteurized cream is cooled to 10°C, packaged in consumer packaging (bottles, bags or plastic packaging) and further cooled in the refrigerator to 2-4°C. The shelf life of cream is no more than 24 hours at these storage temperatures, incl. no more than 18 hours at the manufacturer. Sterilized cream is packaged under aseptic conditions in consumer containers, which are pre-disinfected with a bactericidal lamp or hydrogen peroxide. The shelf life of cream is established by the manufacturer and is determined by the method of heat treatment, type of packaging and packing conditions. The storage temperature of pasteurized cream is from 2 to 4 C, sterilized - up to 20 C. Creamy drinks are made from cream obtained using the technology described above, but with the addition of various fillers to normalized cream before pasteurization (coffee, cocoa, cream, fruit juices). This takes into account the fact that adding a component that does not contain milk fat will lead to a decrease in fat in the finished product. Therefore, before pasteurization and before adding filler, cream must be normalized so that the fat content of the finished product meets the standard requirements. Technology for the production of recombined products Recombined dairy products often appear in places where there is no production of milk and its processing into dairy products at all. In connection with the shortage of raw milk, as well as in order to improve the supply of dairy products to the population, it became necessary to recognize recombined products as a source of meeting market needs. Therefore, all standards for dairy products are based on the use of fresh natural, reconstituted and recombined milk. To recombine dairy products, three types of ingredients are used: low-fat milk raw materials, fats and various fillers. Low-fat dairy raw materials are skimmed milk powder, buttermilk powder, whole milk powder, milk protein concentrate, caseinate, whey protein concentrate, whey powder. lactose. Anhydrous milk fat, frozen milk fat, frozen butter, special milk fats, dry cream, frozen cream, and vegetable fats are used as fats.

Storage conditions and periods Milk is packaged in tanks and flasks from which it is sold. Milk is packaged in bottles with a capacity of 0.25; 0.5 and 1 l, in paper bags made of grease-proof cardboard with polymer coatings, in bags made of polyethylene film filled with titanium. Paper bags can be of different shapes: tetra-pack (triangular prism), pure-pack (high column with a square base), tetra-brick (brick-shaped). A lot depends on the shape of the package: ease of purchase for the buyer, type of transport container, stability of the packaging during production and distribution. The sharper the corners in the bags (tetra-pack), the faster they are damaged and leak, which entails certain losses. For stacking tetra-packs, special containers have been developed and used - hexagonal boxes made of low-density polyethylene. Milk in pure-pack and tetra-brick packages in blocks of 10-12 pcs. covered with shrink film and placed in packaging equipment. Inn-Pak - a soft polymer bag is also convenient for the distribution of milk. The use of these packages eliminates the need to use returnable glass containers. However, we must remember that all polymer containers are not yet recycled and pollute the environment. Cream is sold only in packaged form in containers with a capacity of 0.25 and 0.5 liters. On the aluminum cap of glass containers, bags, the name of the product, name or number, trademark of the manufacturer, volume in liters, date or day of the last date of sale, retail price, designation of the current standard are applied with embossing or paint. When packaging milk in flasks or thermal tanks, a label with the same details is placed on the container. Additional information for buyers is to print on the packages information about the composition of the product, calorie content, drawings and instructions for opening the container, conditions and shelf life. Package labeling must be clear and colorful. Milk and cream are transported in closed refrigerated or insulated containers; in their absence, the product must be covered with a tarpaulin or other protective material. Cream should be stored at a temperature from 0 to 8 ° C for no more than 36 hours from the end of the technological process. Sterilized milk at temperatures from 0 to 10°C can be stored for up to 6 months, at temperatures from 0 to 20°C - no more than 4. Rooms and chambers for storing milk and cream must be ventilated and darkened. Bulk milk is sold after thorough mixing. It is prohibited to hold the buyer's dishes over an open flask or barrel and pour milk from it back into a common container. You cannot leave equipment in a container with milk - a measuring cup, etc. The equipment is washed daily with a hot soda solution, wiped dry with a clean towel and stored in designated places. You can consume bottled milk only after boiling. A warning notice about this must be placed at the point of sale.

The dairy industry is one of the most important sectors of the agro-industrial complex for providing the population with food. It represents a widely branched network of processing enterprises and includes the most important industries: whole milk production, butter making, cheese making, production of canned condensed and dry dairy products, ice cream, production of baby food products, whole milk substitutes for young farm animals, as well as cream. Each sub-sector has its own specific characteristics.

Industrial milk processing is a complex complex of interconnected chemical, physicochemical, microbiological, biochemical, biotechnical, thermophysical and other specific technological processes.

The production of cream is based on the processing of individual components of milk. Cream can be natural (obtained by separating whole cow's milk) and reconstituted from dry cream. For direct consumption, it is produced in pasteurized and sterilized form. The technological process for producing cream is similar to the process for producing drinking milk and includes the following operations: quality assessment and acceptance of milk, cleaning, cooling, reserving, separating milk to obtain cream. normalization for fat, homogenization, pasteurization, cooling, packaging, storage.

Technological processes for the production of cream consist of separate technological operations that are performed on different machines and devices that are assembled into technological lines.

Put into effect by order of the Federal Agency for Technical Regulation and Metrology dated June 28, 2013 N 269-st

Interstate standard GOST 31451-2013

"DRINKING CREAM. TECHNICAL CONDITIONS"

Drinking cream. Specifications

Introduced for the first time

Preface

The goals, basic principles and basic procedure for carrying out work on interstate standardization are established by GOST 1.0-92 "Interstate standardization system. Basic provisions" and GOST 1.2-2009 "Interstate standardization system. Interstate standards, rules and recommendations for interstate standardization. Rules for development, adoption, application, renewal and cancellation"

1 area of use

This standard applies to drinking cream packaged in consumer containers after heat treatment or heat-treated in consumer containers (hereinafter referred to as the product) intended for direct use as food.

This standard does not apply to products enriched with milk protein, vitamins, micro- and macroelements, dietary fiber, polyunsaturated fatty acids, phospholipids, probiotics and prebiotics.

Requirements ensuring product safety are set out in 5.1.4, 5.1.5, quality requirements - in 5.1.2, 5.1.3, labeling requirements - in 5.3.

2 Normative references

This standard uses normative references to the following interstate standards:

GOST 8.579-2002 State system for ensuring the uniformity of measurements. Requirements for the quantity of packaged goods in packages of any type during production, packaging, sale and import

GOST 1349-85 Canned milk. Dry cream. Specifications

GOST 2493-75 Reagents. Potassium phosphate disubstituted 3-water. Specifications

GOST 3622-68 Milk and dairy products. Sampling and preparing them for testing

GOST 3623-73 Milk and dairy products. Methods for determining pasteurization

GOST 3624-92 Milk and dairy products. Titrimetric methods for determining acidity

GOST 4172-76 Reagents. Sodium phosphate disubstituted 12-water. Specifications

GOST 4495-87 Whole milk powder. Specifications*2

GOST 5538-78 Reagents. Potassium citrate 1-water. Specifications

GOST 5867-90 Milk and dairy products. Fat determination methods*3

GOST 9225-84 Milk and dairy products. Microbiological analysis methods*4

GOST 10970-87 Skimmed milk powder. Specifications*5

GOST 14192-96 Marking of cargo

GOST 22280-76 Reagents. Sodium citrate 5, 5-water. Specifications

GOST 23285-78 Transport bags for food products and glass containers. Specifications

GOST 23452-72 Milk and dairy products. Methods for determining residues of organic chlorine pesticides

GOST 25228-82 Milk and cream. Method for determining heat resistance using an alcohol test

GOST 25776-83 Piece products in consumer packaging. Group packaging in shrink film

GOST 26663-85 Transport packages. Formation using packaging tools. General technical requirements

GOST 26809-86 Milk and dairy products. Acceptance rules, sampling methods and sample preparation for analysis

GOST 28283-89 Cow's milk. Method for organoleptic evaluation of smell and taste

GOST 26927-86 Raw materials and food products. Methods for determining mercury

GOST 26932-86 Raw materials and food products. Lead determination methods

GOST 26933-86 Raw materials and food products. Methods for determining cadmium

GOST 30178-96 Raw materials and food products. Atomic absorption method for determining toxic elements

GOST 30347-97 Milk and dairy products. Methods for determining Staphylococcus aureus

GOST 30519-97 Food products. Method for detecting bacteria of the genus Salmonella

GOST 30538-97 Food products. Methodology for determining toxic elements using the atomic emission method

GOST 30711-2001 Food products. Methods for identifying and determining the content of aflatoxins B 1 and M 1

GOST 31449-2013 Raw cow's milk. Specifications

Note - When using this standard, it is advisable to check the validity of the reference standards in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet or using the annual information index "National Standards", which was published as of January 1 of the current year, and according to the releases of the monthly information index "National Standards" for the current year. If the reference standard is replaced (changed), then when using this standard you should be guided by the replacing (changed) standard. If the reference standard is canceled without replacement, then the provision in which a reference is made to it is applied in the part that does not affect this reference.

3 Terms and definitions

In this standard, the following term is used with the corresponding definition:

3.1 drinking cream: Cream subjected to heat treatment (at least pasteurization) and packaged in consumer containers.

4 Classification

4.1 Depending on the dairy raw material, the product is made from:

Normalized cream;

Reconstituted cream;

Mixtures of them.

4.2 The product according to 4.1, depending on the heat treatment mode, is divided into:

Pasteurized;

Sterilized;

Ultra-pasteurized.

5 Technical requirements

5.1 Key indicators and characteristics

5.1.1 The product is manufactured in accordance with the requirements of this standard according to technological instructions in compliance with hygienic requirements for dairy industry enterprises operating in the territory of the state that has adopted the standard.

5.1.2 In terms of organoleptic characteristics, the product must meet the requirements of Table 1.

Table 1

5.1.3 In terms of physical and chemical indicators, the product must comply with the standards specified in Table 2.

table 2

|

Indicator name |

Standard for a product with a mass fraction of fat, %, not less |

|||

|

10, 0; 11, 0; 12, 0; 13, 0; 14, 0; 15, 0; 16, 0; 17, 0; 18, 0 |

25, 0; 26, 0; 27, 0; 28, 0 | |||

|

Mass fraction of protein, %, not less | ||||

|

Acidity, °T, no more | ||||

|

Phosphatase or peroxidase (for pasteurized, baked and UHT product without aseptic filling) |

Not allowed |

|||

|

Temperature of the product upon release from the enterprise, °C: | ||||

|

For pasteurized, ultra-pasteurized (without aseptic filling); | ||||

|

For UHT (with aseptic filling) and sterilized | ||||

5.1.4 Permissible levels of potentially hazardous substances (toxic elements, mycotoxins, dioxins, melamine, antibiotics, pesticides, radionuclides) in the product must not exceed the requirements.

5.1.5 Permissible levels of microorganisms (QMAFAnM, coliforms, pathogenic microorganisms, including salmonella, staphylococcus S.aureus, listeria L.monocytogenes) in pasteurized and ultra-pasteurized products without aseptic filling should not exceed the requirements.

5.1.6 Sterilized and ultra-pasteurized products with aseptic filling must meet the requirements of industrial sterility established by regulations in force in the territory of the states that have adopted the standard.

5.2 Requirements for raw materials

5.2.1 The following raw materials are used for the manufacture of pasteurized product:

Raw cow's milk in accordance with GOST 31449 and regulatory and technical documents in force in the countries that have adopted the standard;

Whole milk powder in accordance with GOST 4495 and regulatory and technical documents in force in the countries that have adopted the standard;

Skimmed milk powder in accordance with GOST 10970 and regulatory and technical documents in force in the countries that have adopted the standard;

Dried cream in accordance with GOST 1349 and regulatory and technical documents in force in the countries that have adopted the standard;

5.2.2 For the manufacture of sterilized and ultra-pasteurized products, the following raw materials are used:

Raw cow's milk in accordance with GOST 31449 and regulatory and technical documents in force in the territory of the states that have adopted the standard, with an acidity of no more than 18.0 °T, with a somatic cell content of no more than 500 thousand/cm 3, heat resistance according to alcohol test not lower than the second group according to GOST 25228;

Skimmed milk is a raw material according to regulatory and technical documents in force in the countries that have adopted the standard;

Cream - raw materials according to regulatory and technical documents in force in the countries that have adopted the standard;

Powdered whole milk according to GOST 4495, spray dried, acidity not more than 18 °T, heat resistance according to the alcohol test after reconstitution is not lower than the second group according to GOST 25228;

Skimmed milk powder according to GOST 10970, spray dried, acidity not more than 19 °T, heat resistance according to the alcohol test after reconstitution is not lower than the second group according to GOST 25228;

Dry cream according to GOST 1349, acidity from 15 to 18 °T, heat resistance according to alcohol test after reconstitution is not lower than the second group according to GOST 25228;

Drinking water according to regulatory documents in force in the territory of the states that have adopted the standard.

For sterilized and ultra-pasteurized products, it is allowed to use stabilizer salts:

Sodium citrate 5, 5-water according to GOST 22280;

Potassium citrate trisubstituted 1-water according to GOST 5538;

Potassium phosphate disubstituted 3-water according to GOST 2493;

Sodium phosphate disubstituted 12-water according to GOST 4172.

5.2.3 The raw materials used to manufacture the product must meet the safety requirements.

5.2.4 It is allowed to use similar raw materials of domestic and other production that are not inferior in quality and safety indicators specified in 5.2.1 - 5.2.3.

5.3 Marking

5.3.1 Labeling of consumer packaging is carried out in accordance with.

5.3.2 Marking of group packaging, reusable and transport containers, transport package - in accordance with the application of handling signs or warning notices: “Keep away from sunlight” and “Temperature limit” indicating the minimum and maximum temperature values according to GOST 14192, regulatory and technical documents valid in the territory of the states that have adopted the standard.

5.3.3 When banding with transparent polymeric materials, markings may not be applied to the side surfaces of the group packaging, transport containers and transport package. In this case, markings are visible inscriptions on consumer packaging or group packaging, or transport packaging, supplemented by information on the number of pieces and gross weight. Non-visible inscriptions, including manipulation marks, are applied to insert sheets or presented in any other available way.

5.4 Packaging

5.4.1 Containers and materials used for packaging and sealing the product must comply with the requirements of the documents in accordance with which they are manufactured, and ensure the preservation of the quality and safety of the products during their transportation, storage and sale.

5.4.2 Formation of group packaging - in accordance with GOST 25776.

5.4.3 Transport packages are formed in accordance with GOST 23285 and GOST 26663.

5.4.4 The transport package is laid out so that the marking of at least one unit of consumer packaging and/or group packaging, and/or transport packaging, and/or reusable packaging is visible on each side of the transport package.

The transport package is laid in ways that ensure the safety of the bottom rows of consumer packaging and/or group packaging, and/or shipping packaging, and/or reusable packaging without deformation.

5.4.5 Permissible negative deviations of the net content from the nominal quantity - in accordance with GOST 8.579.

6 Acceptance rules

6.1 Acceptance rules - in accordance with GOST 26809 and regulatory documents in force in the countries that have adopted the standard.

6.2 The product is controlled according to the quality and safety indicators provided for in section 5, in accordance with the production control program approved in the prescribed manner.

7 Control methods

7.1 Selection and preparation of samples for analysis - in accordance with GOST 26809 and regulatory documents in force in the countries that have adopted the standard.

7.2 Determination of appearance, consistency, taste and smell, color is carried out organoleptically and characterized in accordance with the requirements of 5.1.2.

7.3 Determination of the temperature of the product upon release from the enterprise and the net weight of the product - in accordance with GOST 3622 and regulatory documents in force in the territory of states that have adopted the standard.

7.4 Determination of the mass fraction of fat - according to GOST 5867 and regulatory documents in force in the countries that have adopted the standard.

7.5 Determination of the mass fraction of protein - according to regulatory documents in force in the territory of the states that have adopted the standard.

7.6 Determination of acidity - according to GOST 3624 and regulatory documents in force in the countries that have adopted the standard.

7.7 Determination of heat treatment efficiency indicators:

Pasteurization (test for phosphatase or peroxidase) - according to GOST 3623 and regulatory documents in force in the countries that have adopted the standard;

Sterilization, ultra-pasteurization (product with aseptic filling) (compliance with industrial sterility requirements) - according to regulatory documents in force in the countries that have adopted the standard.

7.8 Determination of toxic elements:

Lead - according to GOST 26932, GOST 30178, GOST 30538 and regulatory documents in force in the countries that have adopted the standard;

Arsenic - according to GOST 30538 and regulatory documents in force in the countries that have adopted the standard;

Cadmium - according to GOST 26933, GOST 30178, GOST 30538 and regulatory documents in force in the countries that have adopted the standard;

Mercury - according to GOST 26927 and regulatory documents in force in the countries that have adopted the standard.

7.9 Definition of pesticides - according to GOST 23452 and regulatory documents in force in the countries that have adopted the standard.

7.10 Determination of mycotoxins (aflatoxin M 1) - according to GOST 30711 and regulatory documents in force in the countries that have adopted the standard.

7.11 Definition of antibiotics - according to regulatory documents in force in the territory of the states that have adopted the standard.

7.12 Determination of radionuclides - according to regulatory documents in force in the territory of states that have adopted the standard.

7.13 Determination of the content of GMOs, melamine, dioxins (in case of a reasonable assumption of their possible presence) - according to regulatory documents in force in the territory of the states that have adopted the standard.

7.14 Determination of microbiological indicators:

KMAFAnM, coliforms (coliforms) - according to GOST 9225 and regulatory documents in force in the countries that have adopted the standard;

S.aureus - according to GOST 30347 and regulatory documents in force in the countries that have adopted the standard;

Pathogenic microorganisms, including salmonella, - according to GOST 30519 and regulatory documents in force in the countries that have adopted the standard;

Listeria L.monocytogenes - according to regulatory documents in force in the territory of states that have adopted the standard.

8 Transportation and storage

8.1 The product is transported by specialized vehicles in accordance with the rules for the transportation of perishable goods in force for this type of transport.

8.2 Pasteurized and ultra-pasteurized product (without aseptic filling) is stored at a temperature of (4 ± 2) ° C.

Sterilized and ultra-pasteurized product (with aseptic filling) is stored at a temperature from 2°C to 25°C.

The shelf life of the product from the end of the technological process is set by the manufacturer, taking into account the requirements of regulatory legal acts in the field of food safety.

_______________________

* The date of entry into force of the standard on the territory of states is established by their national standardization bodies.

** On the territory of the Russian Federation, GOST R 52791-2007, GOST R 53946-2010 are in force.

*3 Application on the territory of the Russian Federation in terms of section. 4, from 07/01/2002 to use GOST R 51457-99. The use of rennet and processed cheeses on the territory of the Russian Federation has been discontinued; from 01/01/2014, GOST R 55063-2012 will be used. The use in the territory of the Russian Federation in terms of butter without fillers, butter with fillers, salted butter has been discontinued; from 01/01/2014, use of GOST 55361-2012.

*4 GOST R 53430-2009 is in force on the territory of the Russian Federation.

*5 GOST R 52791-2007 is in force on the territory of the Russian Federation.

Bibliography

Technical Regulations of the Customs Union TR CU 021/2011 "On the safety of food products"

Technical Regulations of the Customs Union TR CU 022/2011 “Food products regarding their labeling”

Technical Regulations of the Customs Union TR CU 005/2011 “On Packaging Safety”